In some manufactured contexts, you will need to consider scheduling production order sorted by some criteria. By default, master planning take into entry the requirement date issued from forecast, min/max or sales order entries. You can retrieve this by exploring any planned production order under the Pegging tab. Sometimes, you would like to sort using different criteria. Some industries doing painting for instance may need to schedule orders from the lighter product to the darker one by using the same cabin paint as a resource. How does it work and what are the limitations ?

Demo use case without the sequencing activated

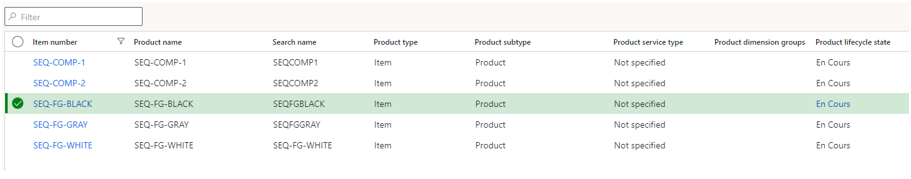

Here are the products I’m using. 3 items differentiated by a color code. They are using the same Route and BOM, but it will take considering time changing the paint on the cabin paint resource that’s why we want to gather the production orders for the same color.

One of the first limitation is the unavailability of dimension (like color dimension or any) to fulfill this process, that’s why I have to duplicate my items.

To better illustrate the process, I’ve setup my resources with finite capacity.

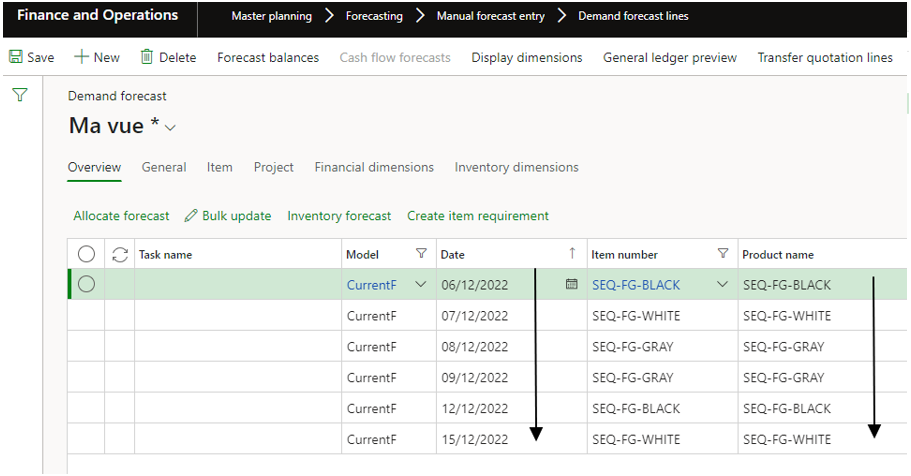

As you can see below, I’ve put some forecast on different colors at different requirement dates.

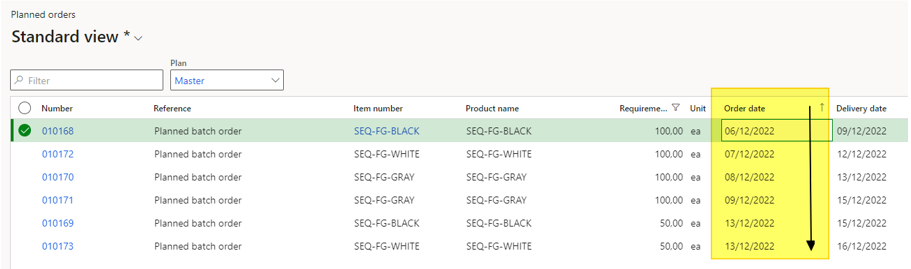

When running the master plan, without doing anything specific so far regarding the sequencing, I have this result sorted by order date which is : Black > White > Gray > Gray > Black > White.

It fits with the forecast I’ve done.

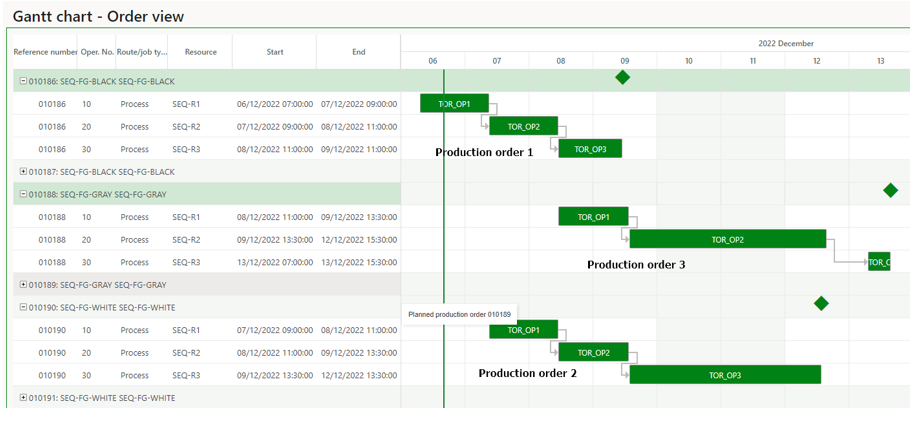

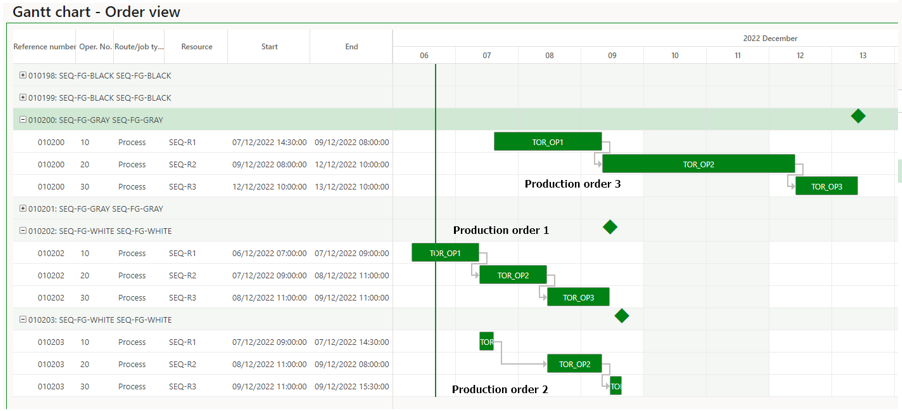

Having a look at the Gantt diagram, we retrieve in a graphic approach this proposal.

Usage of sequences

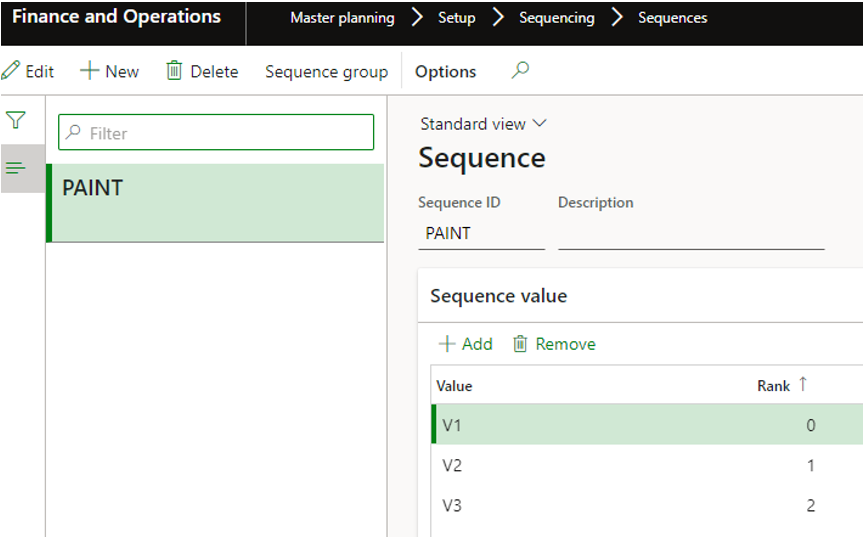

All is happening in the Master planning module. First, go to Master planning > Setup > Sequencing > Sequences and define a Sequence id with values and associated ranks.

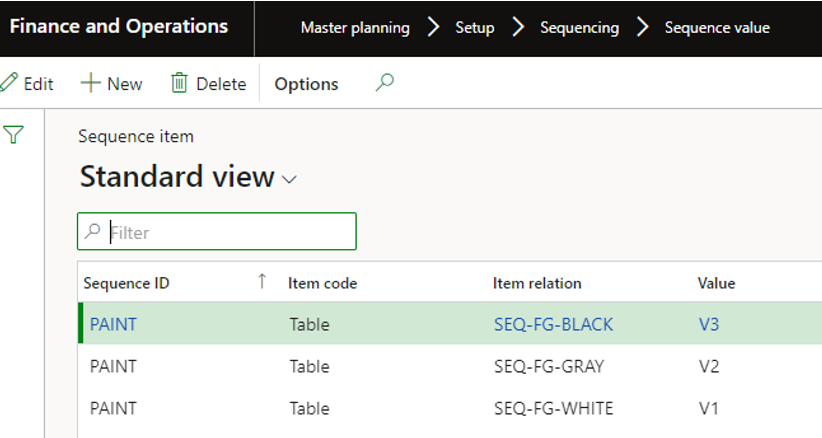

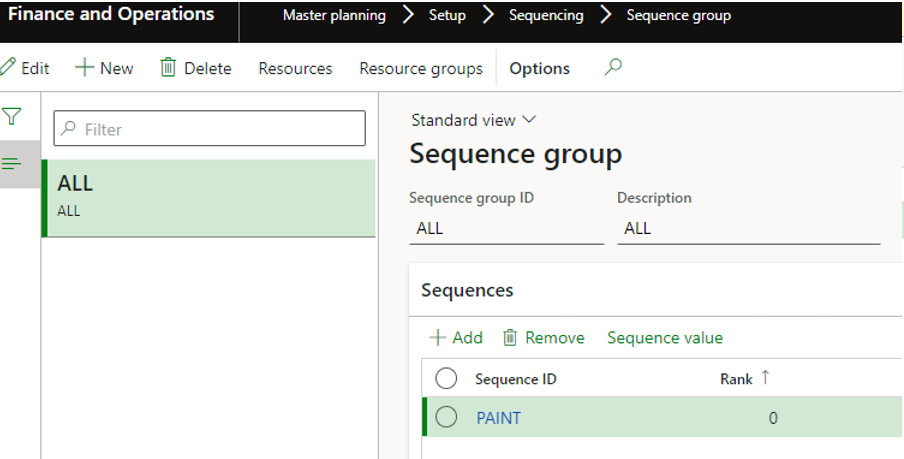

Then, setup a sequence value which is the place to map your items with the ranked value previously done.

No possibility to use any dimension here, unfortunately. Another limitation is that you have to use formula manufactured product only. Why it’s not possible to use other production products remains a mystery to me. There is no objective reason for that. If anyone knows I would like to here it please.

Even when I tried to override it, it’s not working.

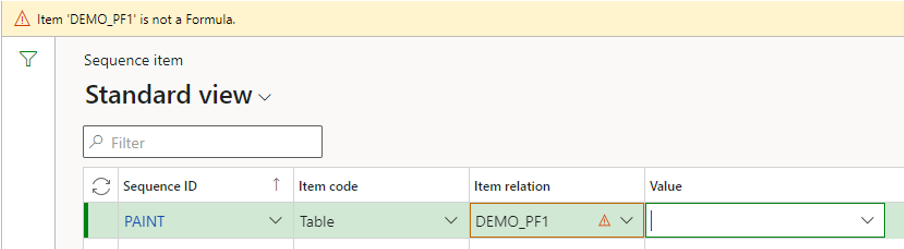

Define then a Sequence group. If you want to combine several groups you can, and then make some rank between them. It’s like advance setup on this feature. According to my tests, it’s also mandatory to have one setup properly like I’ve done.

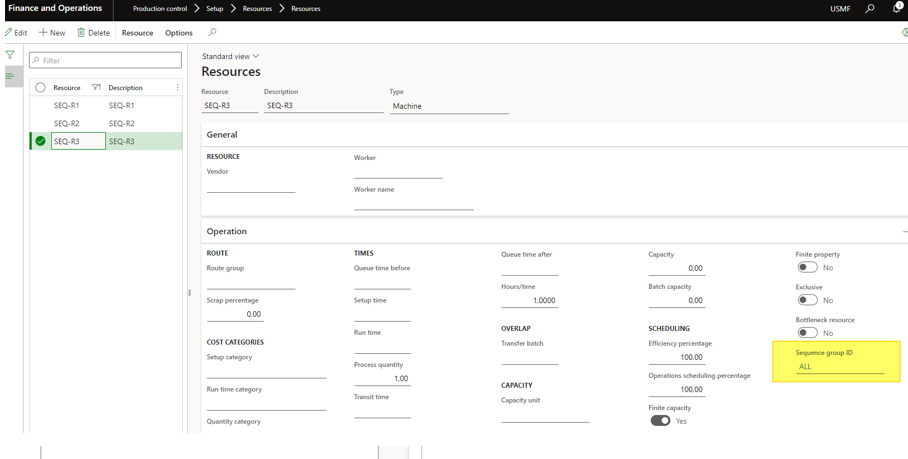

Going now to resources (Production control > Setup > Resources > Resources), you will need to setup the Sequence group ID on each resources of your routes.

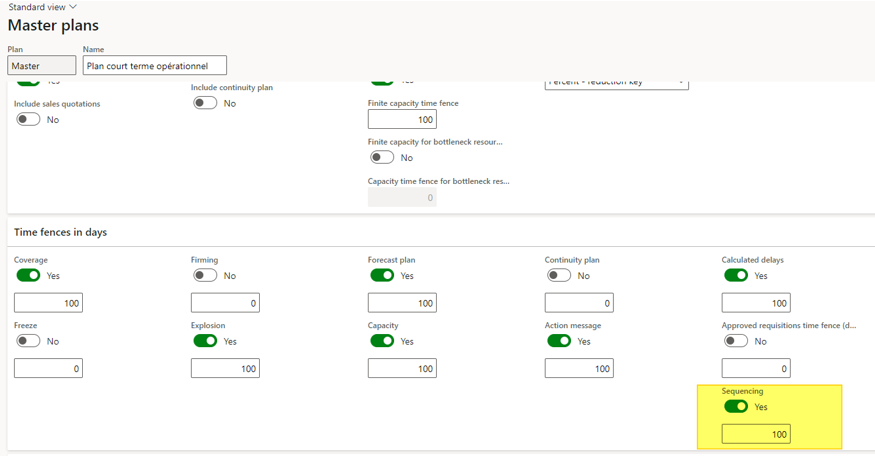

Place to the master plan setup now. Two things to setup in addition to classic setup : in the Time fences in days tab, don’t forget to tick the Sequencing to Yes, otherwise nothing will work.

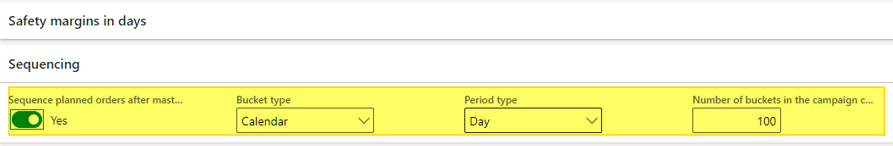

Obviously, in the Sequencing tab, activate the feature and specify a number of Day / period <= coverage time fence.

Now it’s time to run the master plan. The planned production order list will result as the same as previously.

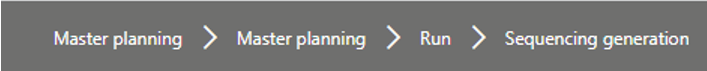

At the end of the master planning execution, you can now run the sequencing generation from Master planning > Master planning > Run > Sequencing generation.

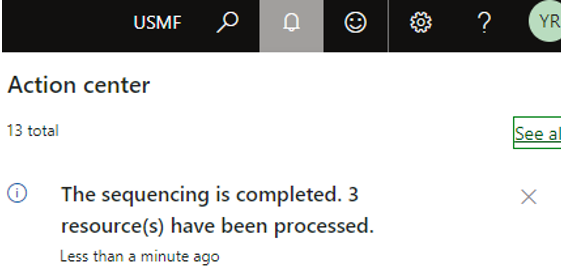

You will get a notification.

This last step is mandatory only if you have setup some filters when running the Master Plan. With a full regeneration without any filter, the sequenced planned orders are automatically generated at the end of the Master planning run.

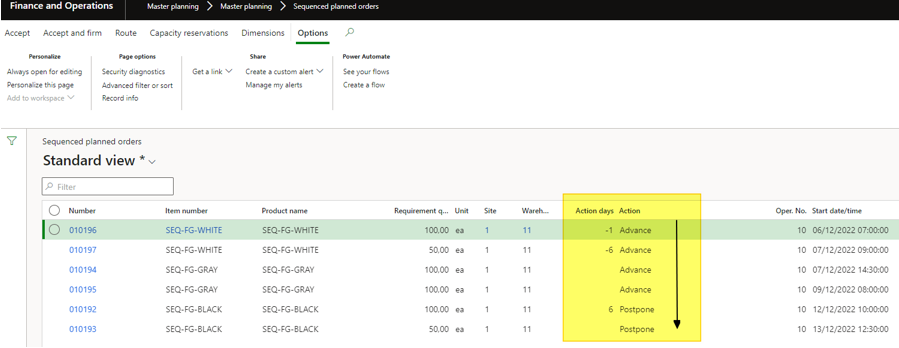

As you can see when opening the Sequenced planned orders form from Master planning > Master planning > Sequenced planned orders form, you will see what actions are propsed by the system. Here it’s adviced to regroup White orders first, then Gray, then Black, as expected.

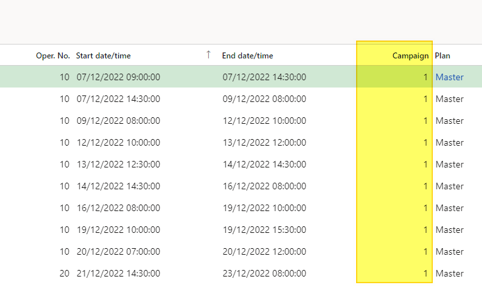

Depending on the time fence of sequencing (“Number of buckets in the campaign cycle”, you may have several campaigns for sorting the sequenced planned orders.

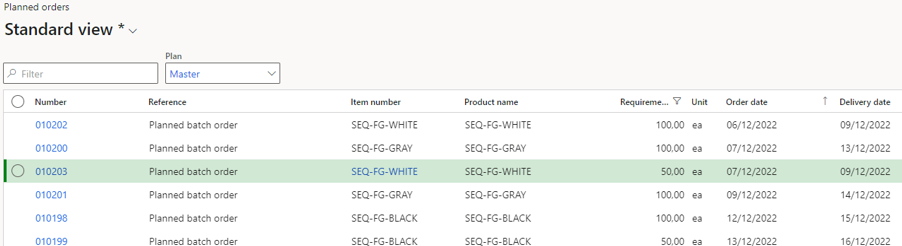

By selection all lines and clicking on Accept, the planned production orders order date are updated.

I’m happy with that. Just curious to notice why a Gray is before a White, it’s because those 2 orders are processing the same day.

Opening the Gantt chart it seems OK.

White orders are the first to be processed. Perfect.

One last comment : as formulas are not yet available in Planning Optimization, it’s not yet possible to use this feature in it yet.

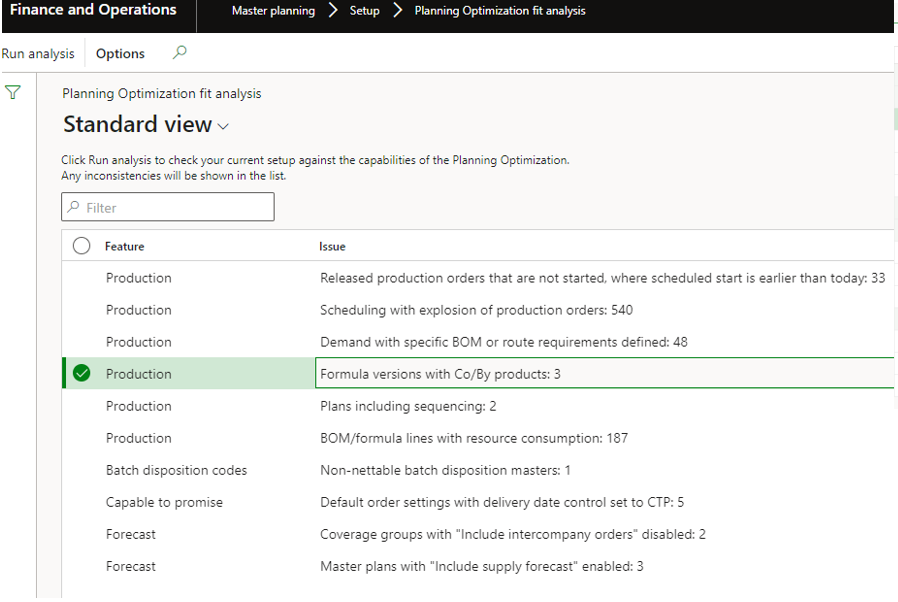

Open the Planning Optimization fit analysis from Master planning > Setup > Planning Optimization fit analysis to see which features are not available yet (don’t forget to Run analysis). As long as not everything is available, you should be able to postpone the mandatory usage of Planning Optimization.

Yohann

PS : Usage of following version for running tests :

Additional resources on the same topic :

https://learn.microsoft.com/en-us/dynamicsax-2012/appuser-itpro/sequence-planned-batch-orders

https://www.loganconsulting.com/blog/production-sequencing-in-d365-with-screenshots/

https://ellipsesolutions.com/d365-sequencing-of-planned-orders-abc-or-123/

One comment