When you’re working with finite capacity resources you want to ensure the master plan take into account those constraints when calculating planned order. This post illustrates the setup required and also explains the impact when enabling the “bottleneck resource” checkbox on resources.

Context and scenario

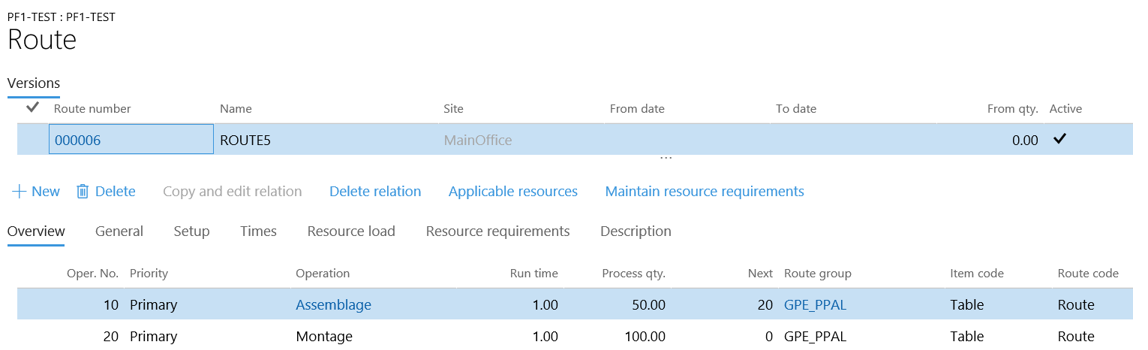

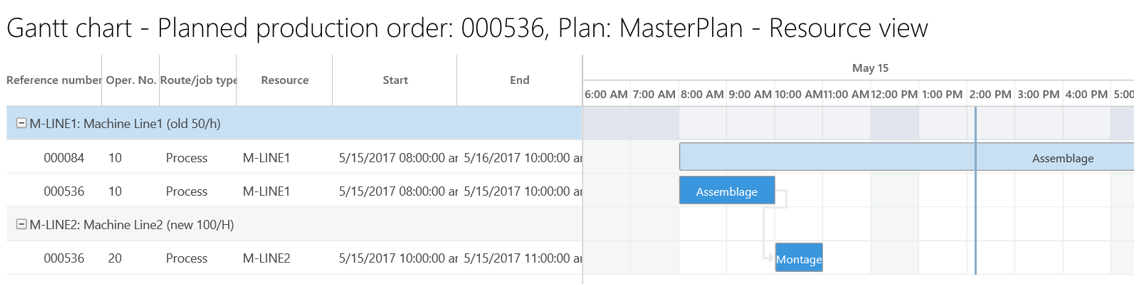

First let’s describe the context. We have a finish good product setup with 2 route operations on his route: the first operation required the M-LINE1 resource which has a process quantity of 50 / hour. M-LINE2 is the applicable resource for the second route operation and has a process quantity of 100 / hour.

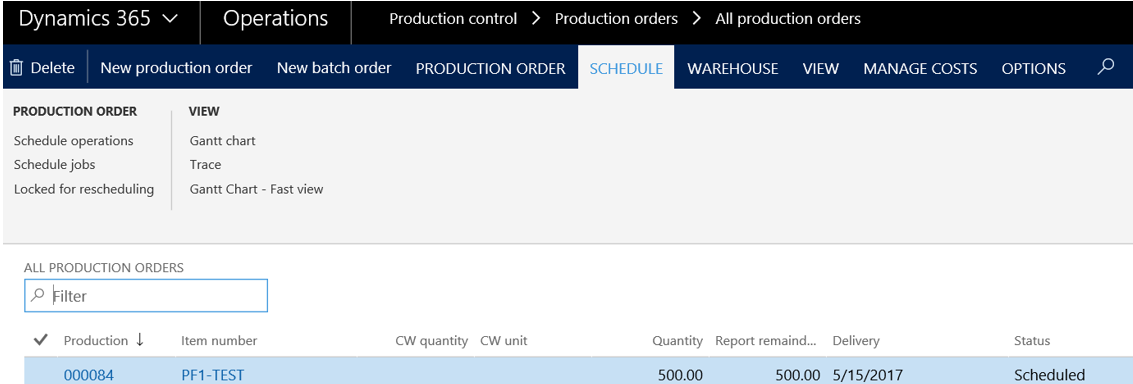

I’m writing this post May the 15th (and it’s important for the time fence setup). We have an existing scheduled production order of 500 for the same product (number 000084).

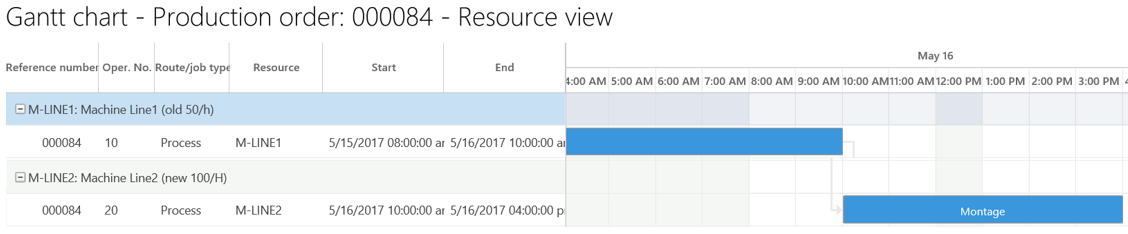

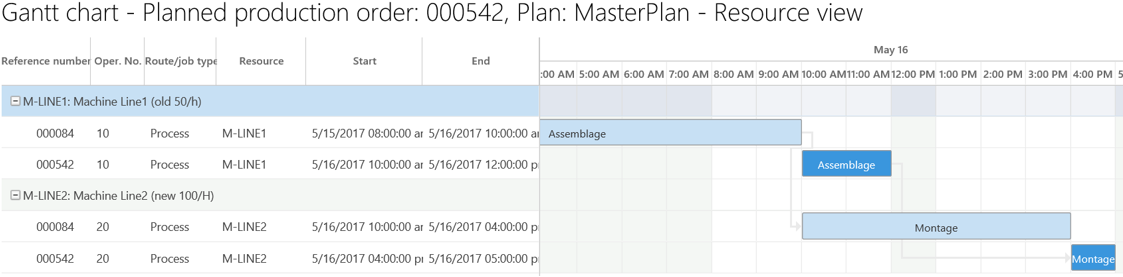

As you can see, the Gantt chart (Click on Gantt chart on the “View” section of the “Schedule tab) has been calculated and the first operation ends tomorrow allowing the second operation to start.

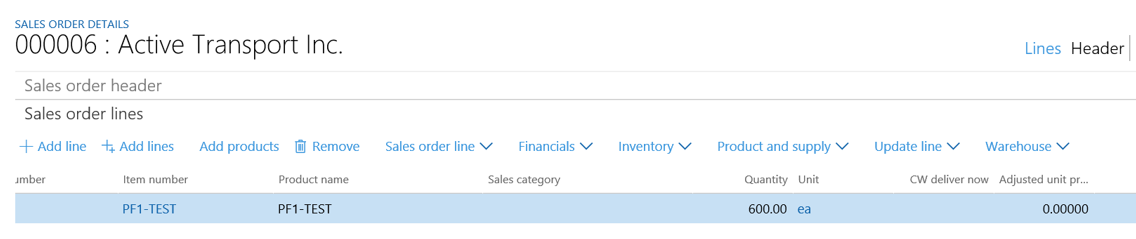

Then, I’ve created a sales order for a delivery date as today (May the 15th) for the same product.

You will need to have this kind of scenario when your resources cannot afford the requirements for testing capacity and bottleneck.

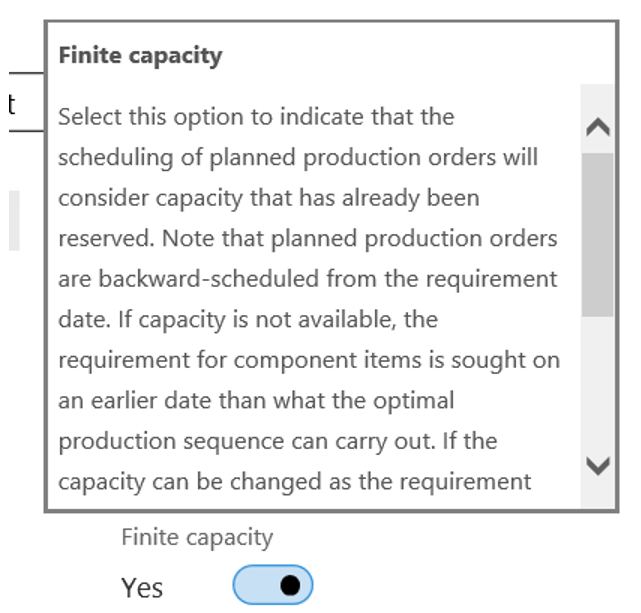

Indeed, by highlighting the checkbox under Master Planning > Setup > Plans > Master Plan, you can guess when you read : “will consider capacity that has already been reserved”.

Setup required

Before running tests, let’s review the required setups.

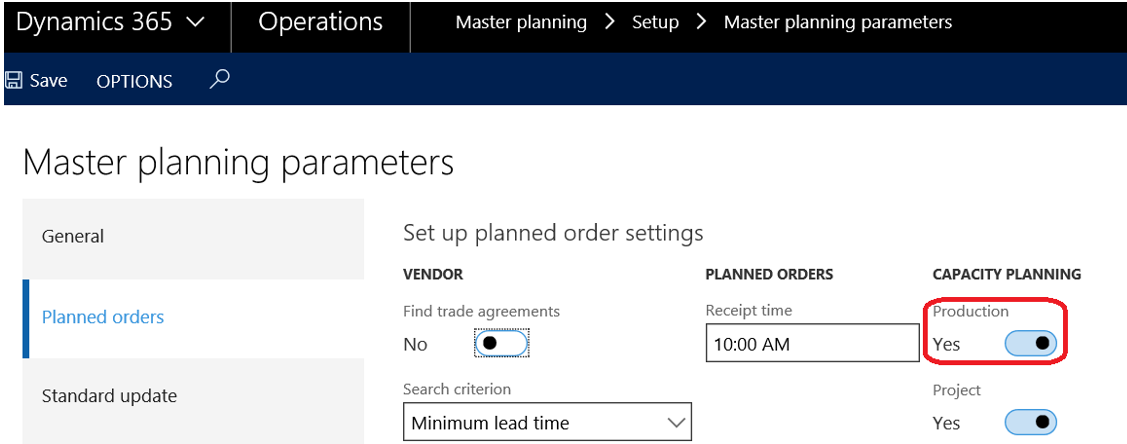

You will need to allow the “Production” checkbox under “Planned order” on Master planning > Setup > Master planning parameters.

You will also need to have at least one coverage group and one master plan (which is the case if you’re testing on a Contoso database like USSI).

Let’s go for testing !

Test1 : without any capacity time fence

Uncheck the Finite capacity checkbox on the master plan you will use for testing (Master Planning > Setup > Plans > Master Plan). It means you are going to plan with infinite capacity.

Run the calculation of the master plan (Master planning > Master planning > Run > Master planning) and analyse the Gantt chart.

The existing production order 000084 is using full the M-LINE1 machine on May the 15th but the system has generated a planned production order scheduled at the same day for covering the sales order. So, it’s clearly an infinite capacity master plan.

Test 2 : with a finite capacity time fence

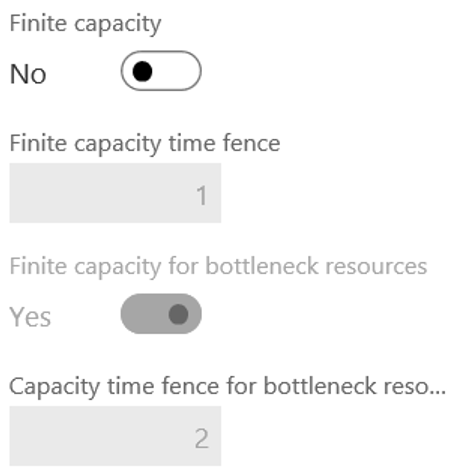

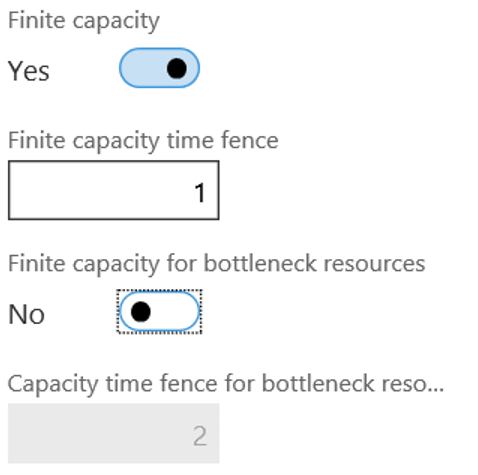

We keep going by activating the “Finite capacity” and “Finite capacity time fence” of 1 day. For now we don’t use the bottleneck option.

Then, we run the master plan and observe the results.

OK, what do we have? The system take into account a time fence of 1 day. It means that during the May 15th the system will not schedule planned order which will use more than 100% of the capacity of resources. On May 15th, the M-LINE1 is full. After the time fence period (1 day), the system does not calculate anything about capacity which is the reason why on May 16th the system has generated the first operation considering infinite capacity on the M-LINE1.

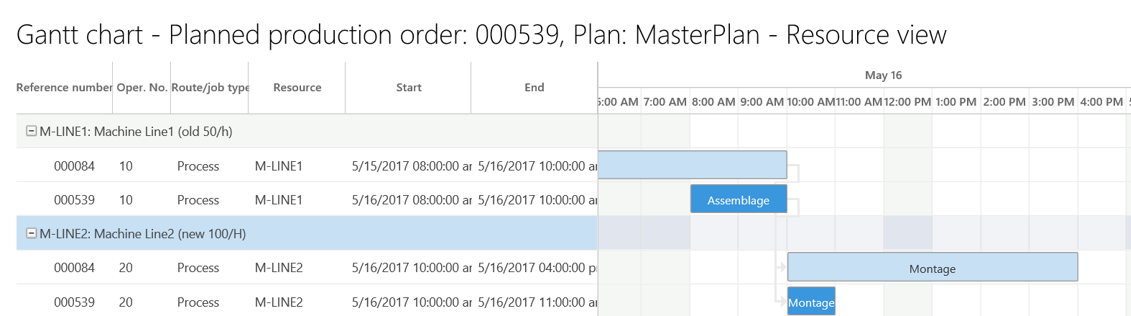

Test 3: with a bigger time fence

If we add one day to the time fence period:

The system will take the capacity into account for the next 2 days that’s why the first operation of the planned production order is scheduled right after the existing production order.

Test 4 : with a bottleneck resource

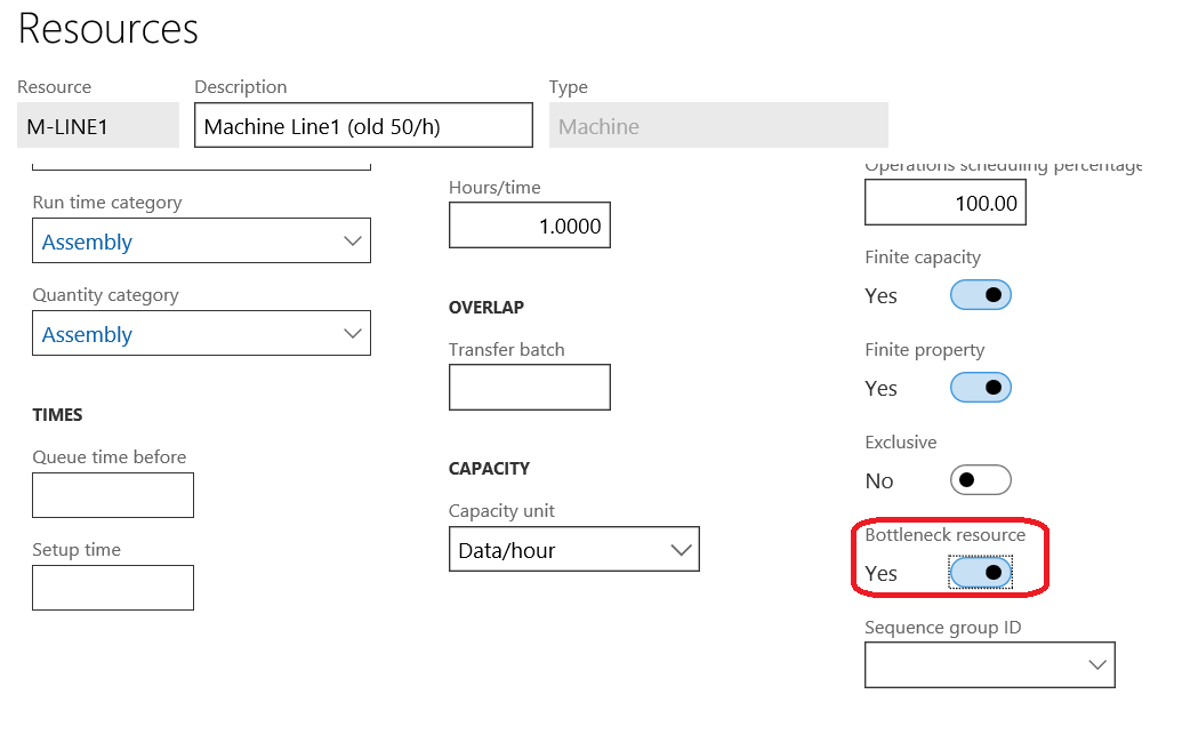

Let’s go deeper and test the impact of a bottleneck resource by enabling the checkbox on the M-LINE1 resource.

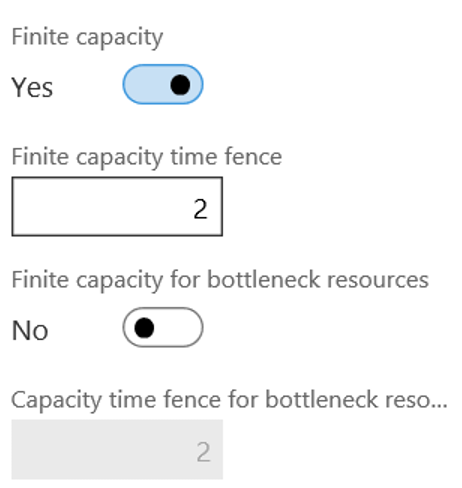

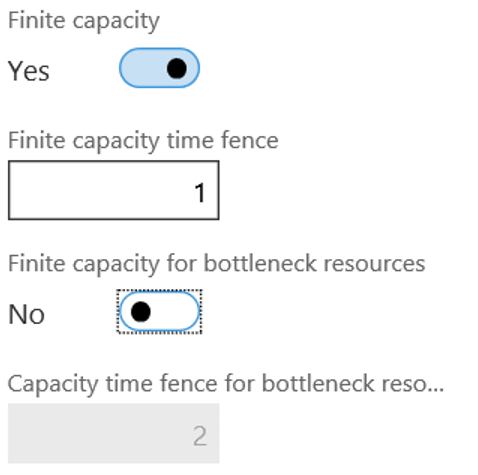

Now, on the master plan used, put the time fence for finite capacity at one day and disable the checkbox for bottleneck resources.

Run the master plan, and observe the results. They are equal to the previous test 2. No impact at this stage. That’s normal because bottleneck resource time fence is not taken into account in the master plan.

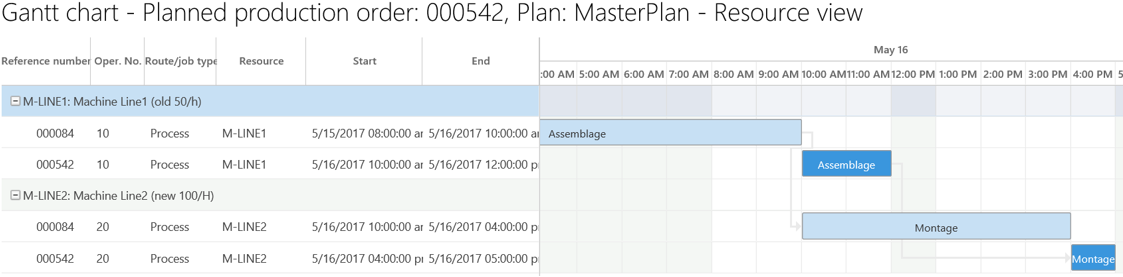

Test 5: activating the time fence for bottleneck resource in the master plan

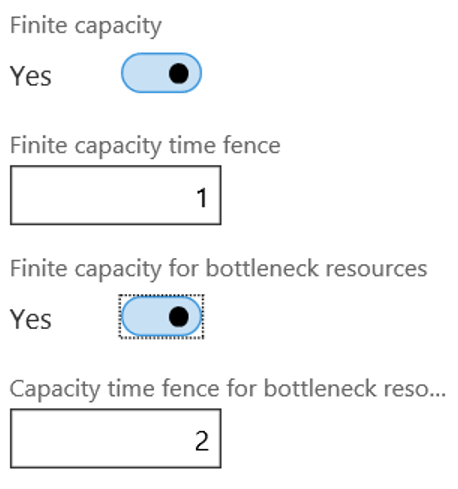

Now, when activating the time fence for bottleneck resource (be sure to have a greater value than finite capacity time fence as it’s advised when highlighting the checkbox), and run the master plan.

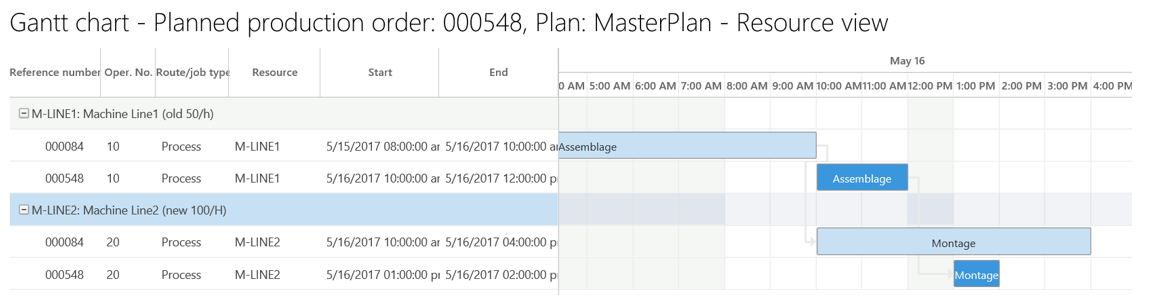

We notice the system will take the capacity into account for the next 2 days for the resource M-LINE1 that’s why the first operation of the planned production order is scheduled right after the existing production order. On the other hand, the resource M-LINE2 is not impacted by the bottleneck time fence as the M-LINE2 is not setup as a bottleneck resource.

Test 6 : update the M-LINE2 resource as a bottleneck one

When doing that and running the master plan, the second resource is also impacted like the M-LINE1 in the previous test.

Conclusion

What is a bottleneck resource in Microsoft Dynamics 365 for Operations ? It allows the system to calculate master plan capacity constraints with a bigger time fence period than the non bottleneck resources. My opinion about that is that it will probably not interested a lot of customers but now we know what this is and how it works. From my experience, customers does not activate some very useful options because they need to setup process as simple as possible so why would they use that one ?

Yohann ROLLAND

Hi,

That’s a very helpful article, thanks. Just I another issue in your scenarios 3 and 6. Planned order’s operations have gap in between. I understand second operation is bottleneck in scenario 6, but do not understand why second one did not immediately start after the first operation. I want to have a result of having two operations without any gap, so move the « Assemblage » just before the « montage ». Is that possible?

Thanks

Hello Arslan,

First you need to check the times tab of your routes because if you have some waiting time between operations it can justify the gap (queue time before, transit time etc).

The system optimize the machine occupation schedule when working in finite capacity. If you want to achieve that I suggest to gather operation 1 et 2 in one same operation.

Otherwise consider working in infinite capacity you won’t have this gap.

Yohann