Version Française disponible ici

Today I’m going to underline some specific setup and functionalities regarding the master planning : let’s have a look on safety stock, Minimum key, Maximum key, Fulfill minimum and Minimum periods available on the item coverage.

Safety stock

It’s not about detailing the coverage code, but you have to know the Minimum field is available not only for the Min/Max coverage code. The minimum means indeed the safety stock under which planned order for replenishment will be generated.

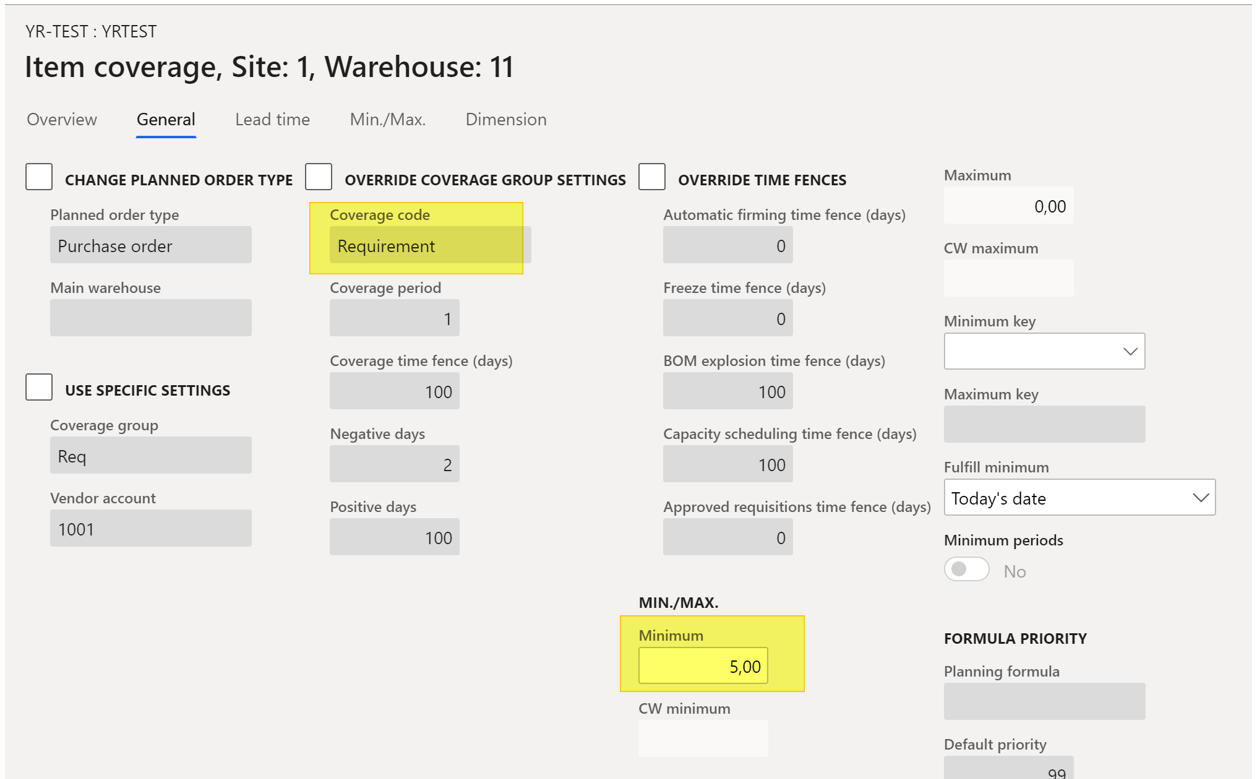

In this first example, I will use the Requirement coverage code (actually I will always use that one for what is next). I have no on-hand inventory, no existing sales orders, and the minimum is setup to 5 as you can see.

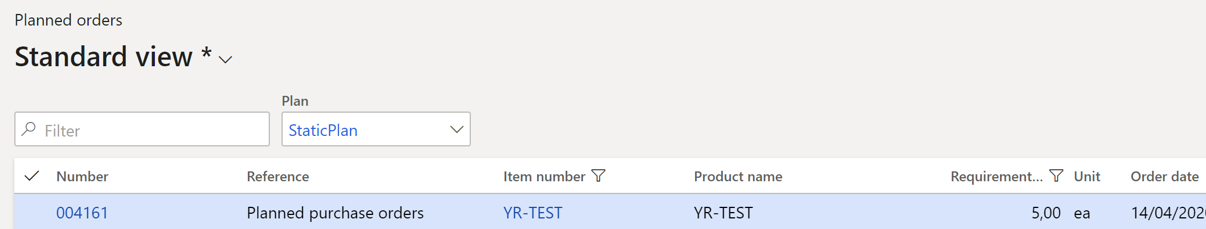

When running the master planning calculation, it results with a planned purchase order for a quantity of 5. Easy to start !

For the second test, I’m just adding a sales order for a quantity of 4, whatever is the delivery date…

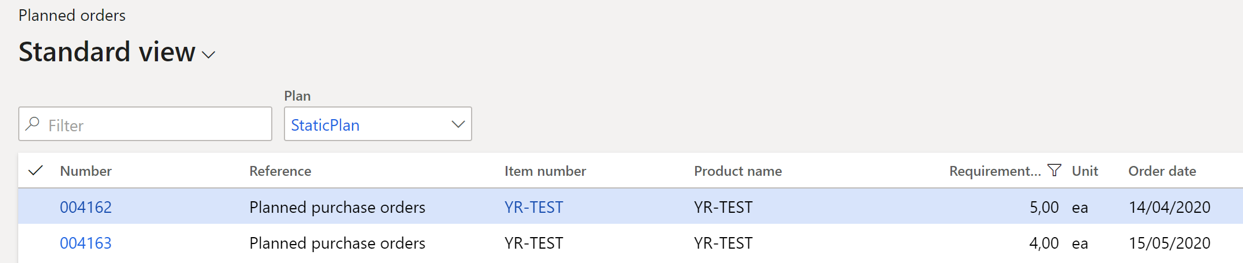

When running the master planning calculation, as my item is covered by a requirement code, I’ve got 2 planned purchase orders with the pegging reference of sales order (for the second one of 4), and safety stock (for the first one of 5).

It was just a recall as there is a lot of blog topics on safety stock. In particular, it’s well explained how you can automatically update the safety stock level for each item by analysing the issues.

Here is some linked :

Fulfill minimum

I was always curious about that setup here, but the existing definition were not enough for me so I decided to run a full test case.

The definition is available under the learn link.

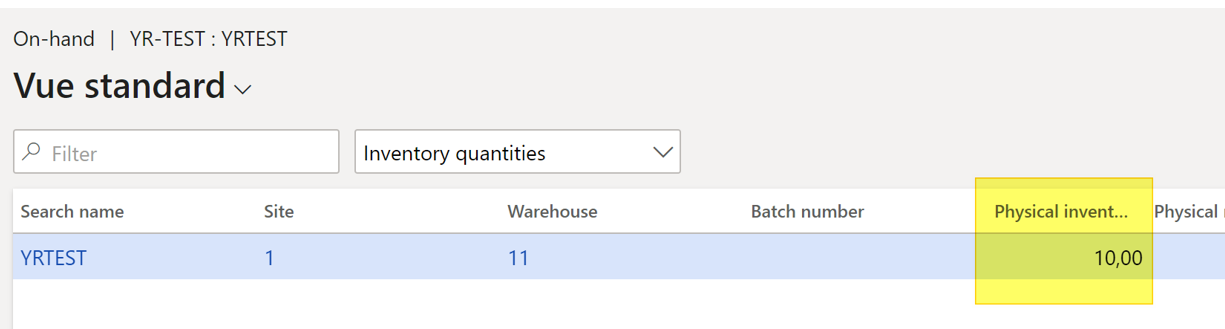

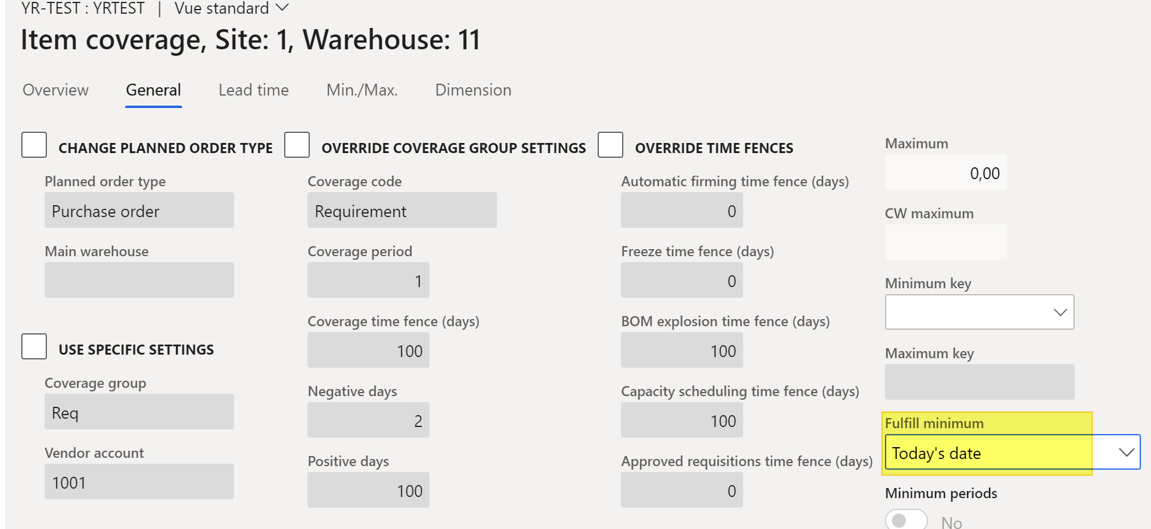

But here we are with concrete data. I’ve got my item, with a on-hand inventory of 10.

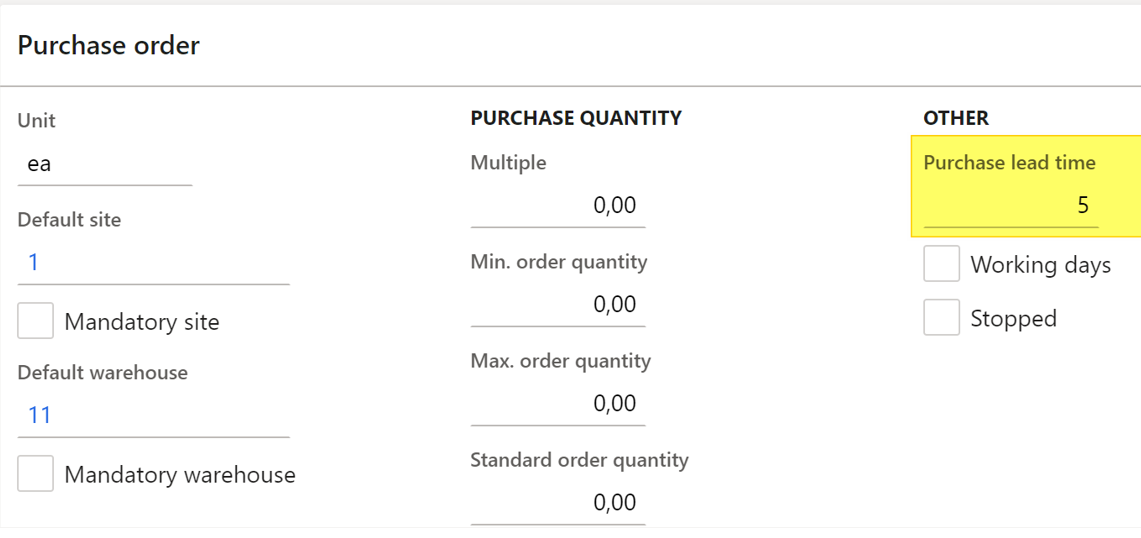

I’ve setup a purchase lead time of 5 days under default order settings. Notice that setup is retrieved under the item coverage form.

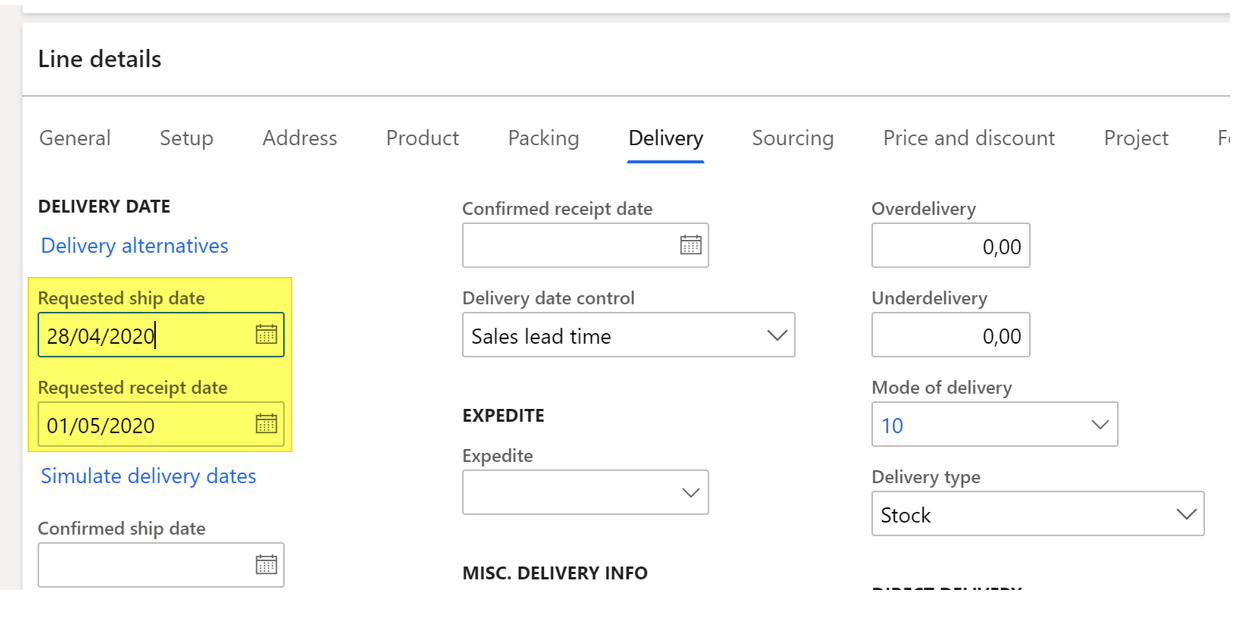

I’ve setup a sales order for a quantity of 6 units with a requested ship date on the 28th of April (so under the safety stock which is now 15).

10 (on hand) – 6 (current sales order) = 4. So I need 11 units to reach my minimum.

Please note that I’m running this test on the 15th April 2020… So today is the 15th. As you can see, my sales order is requested in 13 days from now.

Today’s date

So let’s put the Fulfill minimum to Today’s date. Here is the official definition :

Today’s date – The specified minimum quantity is met on the date when master planning is run. The system tries to fulfill the safety stock limit as soon as possible, even though it can be unrealistic due to the lead time. When the Requirement coverage code is used, multiple planned orders are created. It is always a good idea to use either Period or Min/Max coverage for items and materials in frequent demand to bundle the replenishment.

When running the master planning calculation, what do I have ?

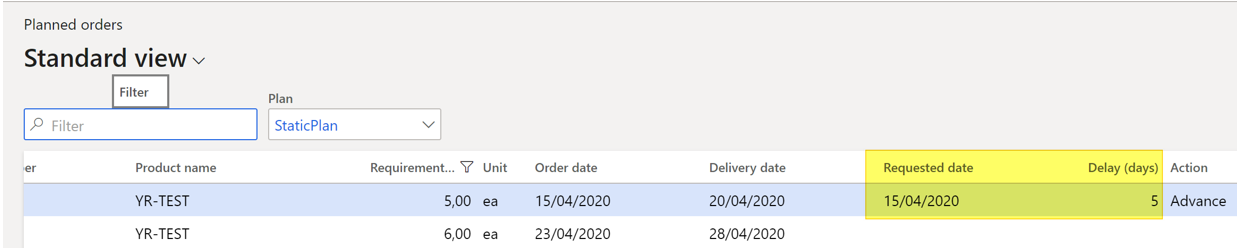

Two orders, looks like previous test… But notice the requested date, it is setup as today ! Also notice the Delay : 5 days. The action advised by the system is to advance the order of 5 days. It has calculated as expected, meaning requested for today.

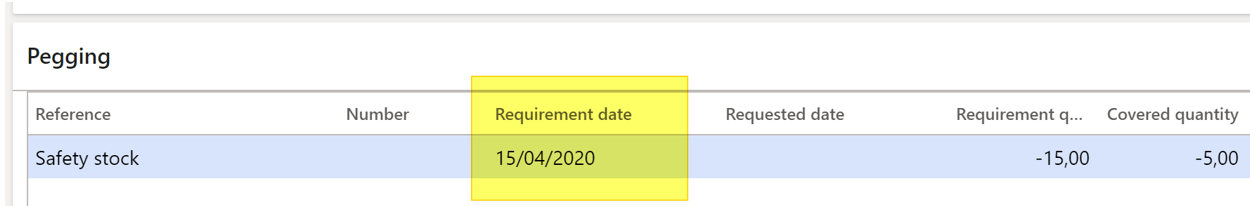

Openning the planned purchase order, the requirement date is setup to today for a quantity to cover of 15 (10 currently on-hand, I need 5 more to fulfill the safety stock).

Today’s date + procurement time

The definition is :

Today’s date + procurement time – The specified minimum quantity is met on the date when master planning is run, plus the purchase or production lead time. This time includes any safety margins.

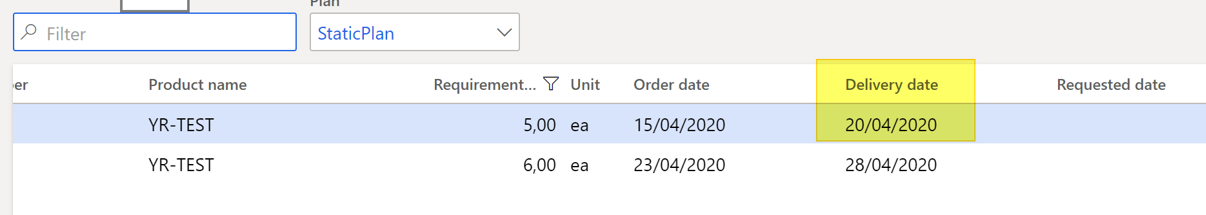

Now let’s change only the Fulfill minimum to Today’s date + procurement time.

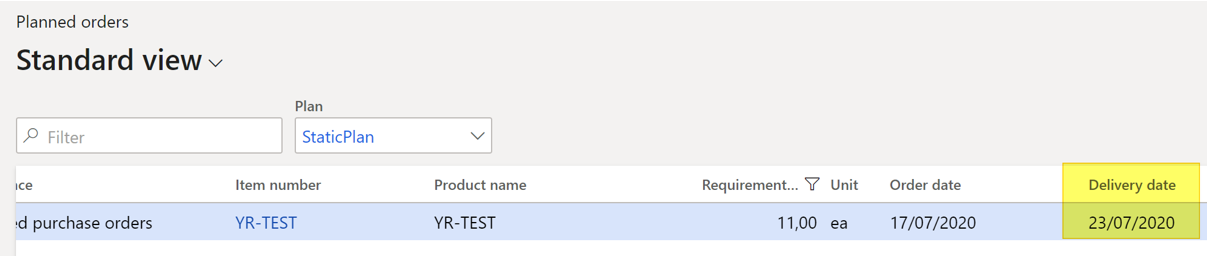

What’s has change when running the master planning calculation ?

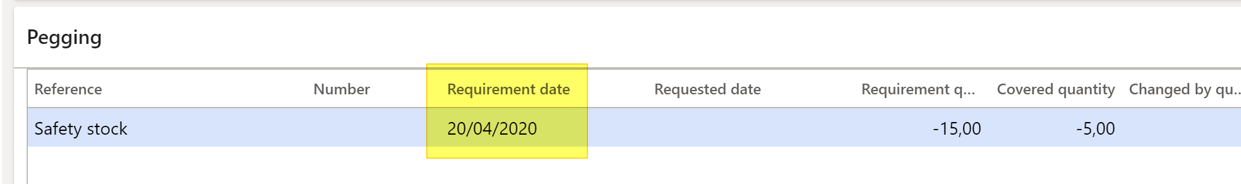

As you can see, the Delivery date is setup to today + 5 days (= purchase lead time), meaning April, the 20th. In this situation, I have not additional delay.

When looking at the requirement date, it is setup to the 20th.

Note that other safety margin are taken into account here but not tested. You can play with those setup available on the item coverage form.

First issue

The definition is :

First issue – The specified minimum quantity is met on the date when the available inventory goes below the minimum level, as shown in the following illustration. Even if the available inventory is below the minimum level on the date when master planning is run, First issue will not attempt to cover it until the next requirement comes in.

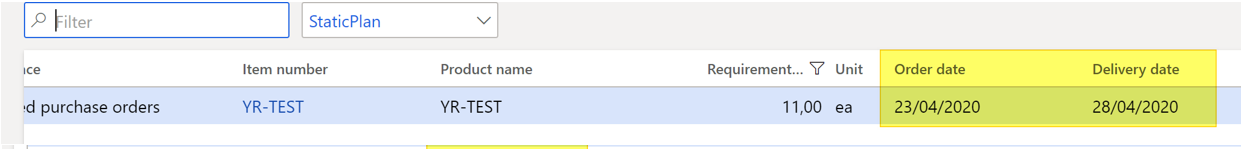

Here it’s very easy, the first issue is my existing sales order with a requested ship date setup on the 28th of April. So here all the needs are gathered until the first issue is found. So it fits with a delivery date on the 28th as you can see below.

Coverage time fence

Coverage time fence – The specified minimum quantity is met during the period that is specified in the Coverage time fence field. This option is useful when master planning does not allow available inventory to be used for real orders, such as sales or transfers, in the attempt to maintain the safety level.

Easy to get it here, as my time fence is setup to 100 days on the item coverage. So the delivery date is calculated to be today + 100.

Now I hope it’s more clear for the Fulfill minimum setup !

Yohann

3 comments