When dealing with CMMS, you can address it by using Field Service Module or Asset Management Module embedded within MSDyn365 for Supply Chain. The big differences between those tools available in the global D365 Platform are :

- Field service applied for customer assets

- Field service can be interfaced with the ERP through Dual Wright but not directly

- Asset Management applied on the ERP’s own assets only

- Asset Management is embedded within the ERP

From a license point of view, Field Service will require a “CRM” license when Asset Management is included with Full / Activities / Team Member standard D365SCM license… Almost. You will be additionally licensed by Dynamics 365 Asset Management Addl Assets for every 100 assets for 84,30 € per month (public price – October 2020).

- The 100 first assets are free

- Beyond 50 Dynamics 365 Asset Management Addl license it’s unlimited (meaning 50 100 assets); you will not require any additional license.

I’m very interesting with any interaction with other modules as it’s embedded. I wanted to explore the capacity of Asset Management by looking at the impact on production lines, Gantt chart and so on.

Here is a tutorial which will show the impact on production orders when a resource/machine is out of service due to corrective or predictive work order.

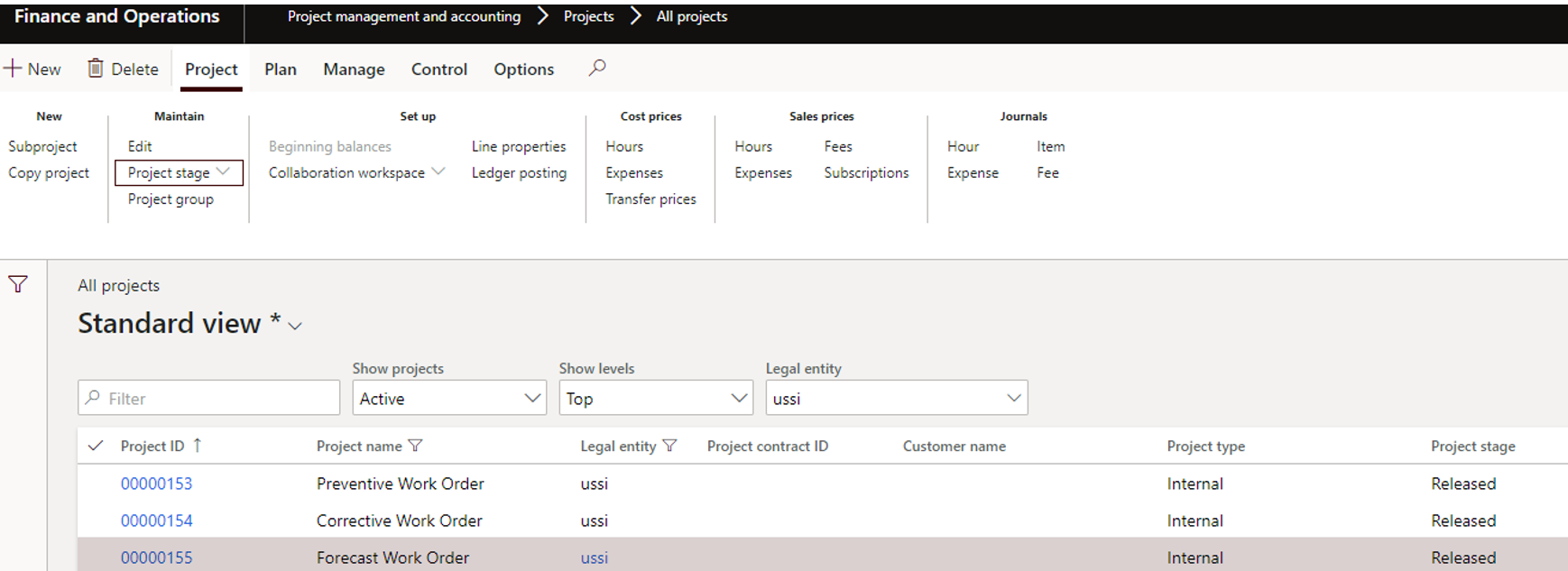

Project setup

After setting up what’s mandatory for making Asset Management module works (Asset type, Functional location, …), you will need to setup internal projects.

Here I have setup 3 of them : one for preventive work orders, one for corrective work orders and the last one is the template for forecasts that will be generated on projects when scheduling a work order.

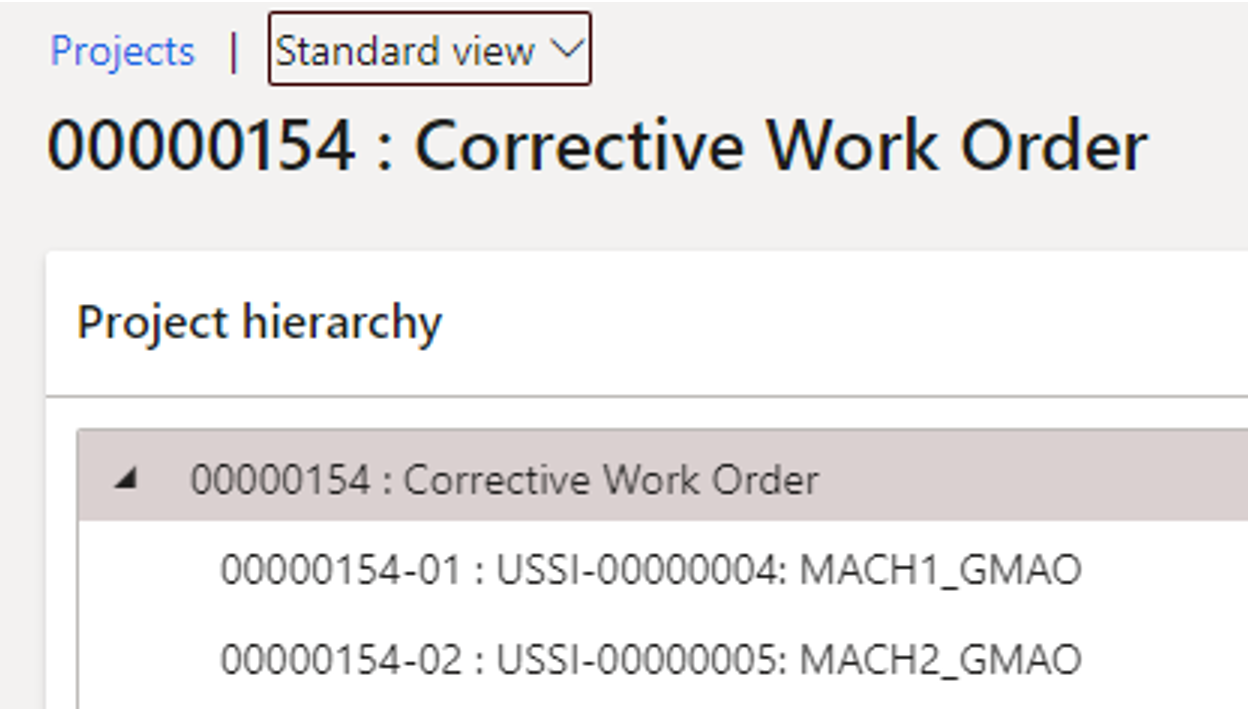

You have to know the interaction with projects. When creating a new work order on a new asset, a new subproject will be created automatically in the correct one (setup to be done in Asset Management module, see below). For my example I’m using those 2.

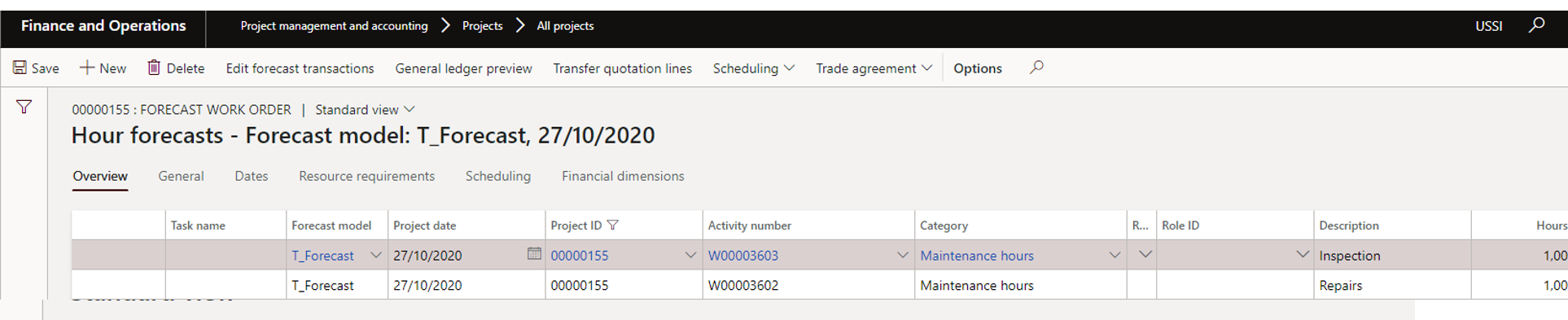

On the 155 project, which is the Forecast template, I’ve setup 2 forecast lines (one for inspections and another one for repairs). I also have created dedicated activities.

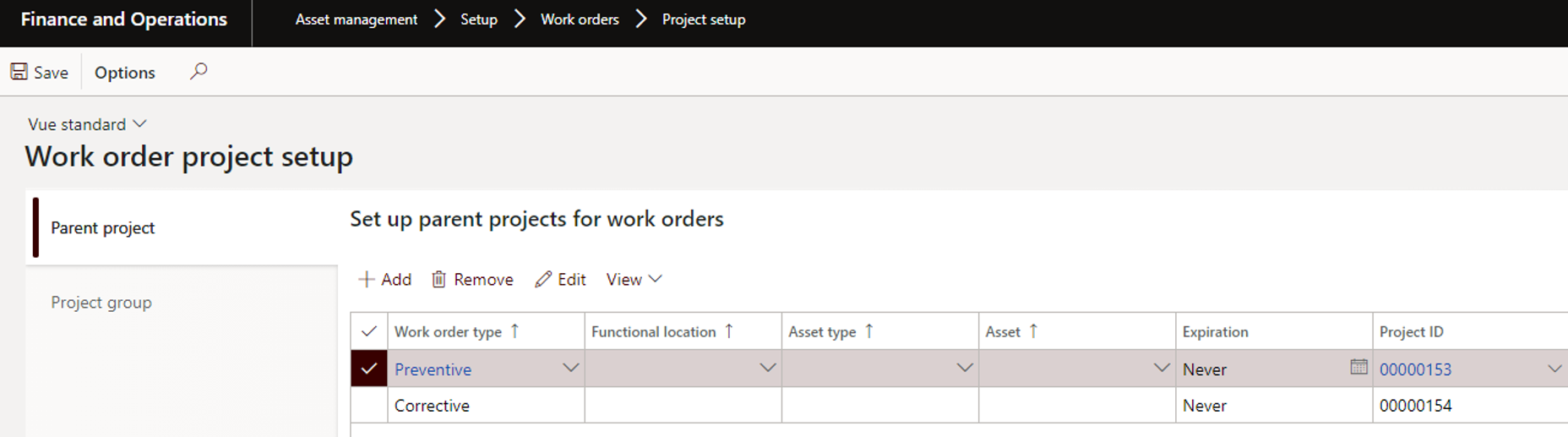

Now going back to Asset Management > Setup > Work orders > Project setup, I’m setting up the appropriate project to use for the correct work order type.

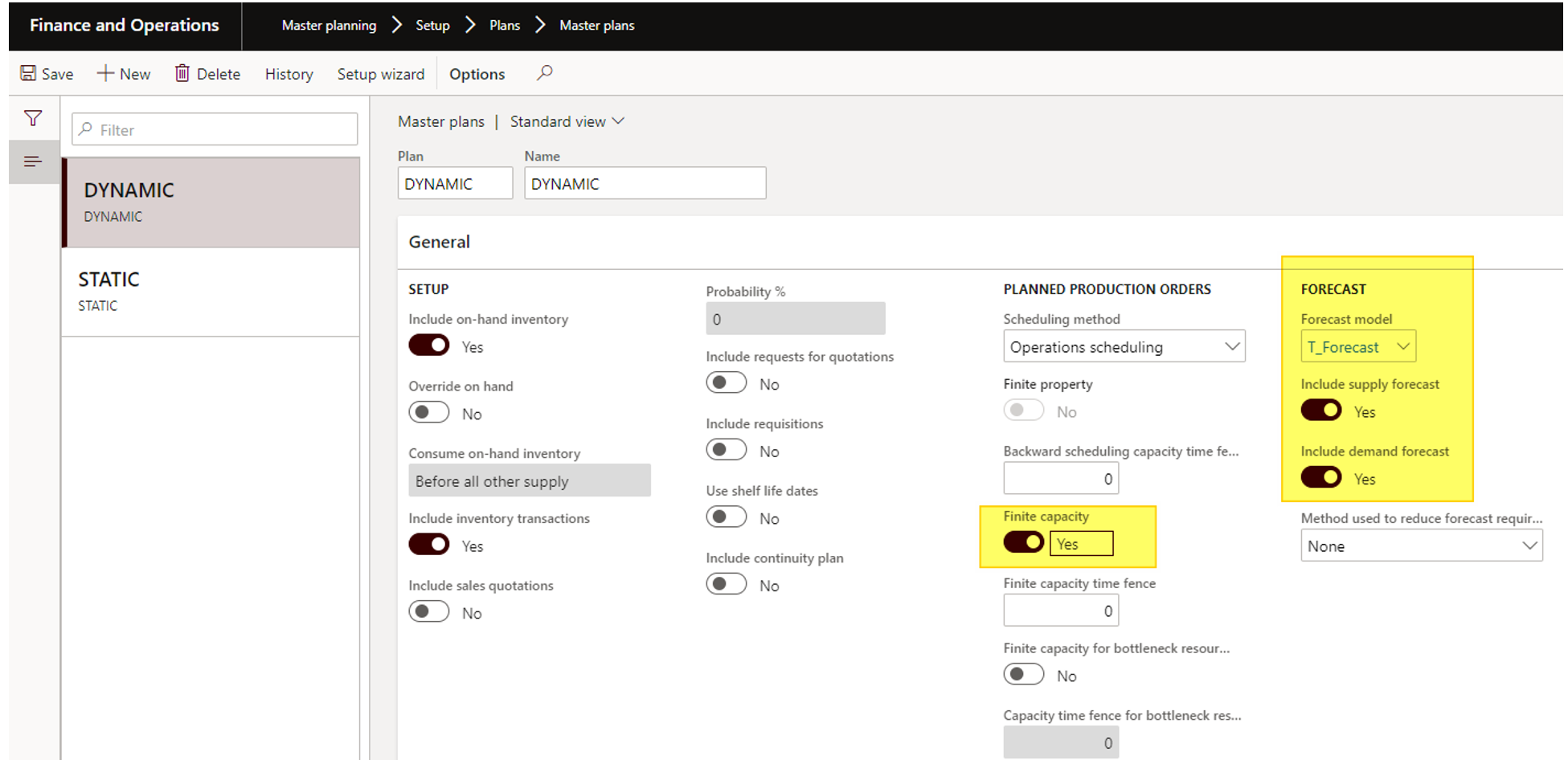

Master Plan Dynamics

In the Master Planning module, I need to have a master plan available, using the correct forecast model and running in Finite capacity.

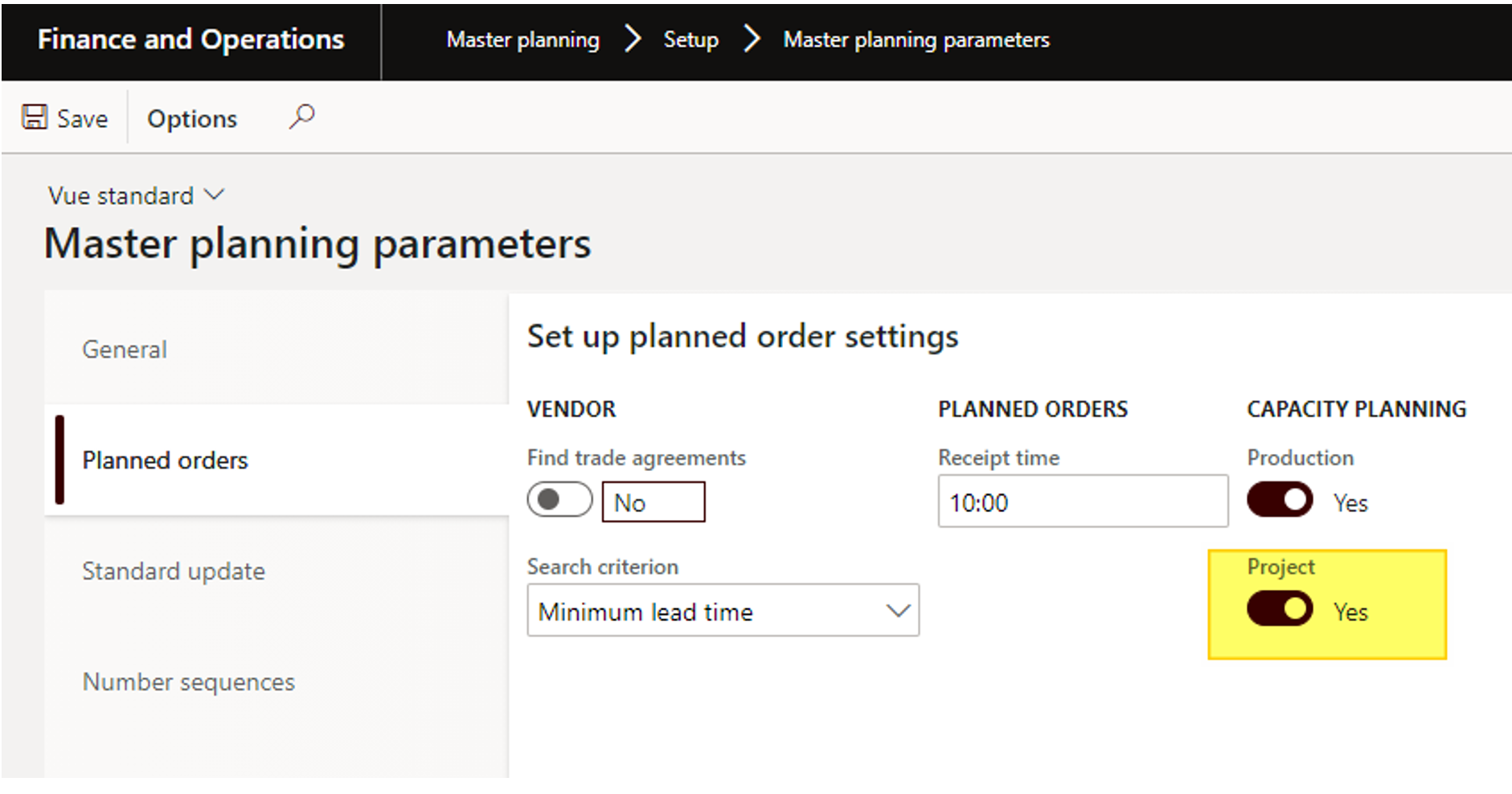

In addition, don’t forget to take Project capacity into account when running Master Plan, in Master planning > Setup > Master planning parameters.

Asset management global setup

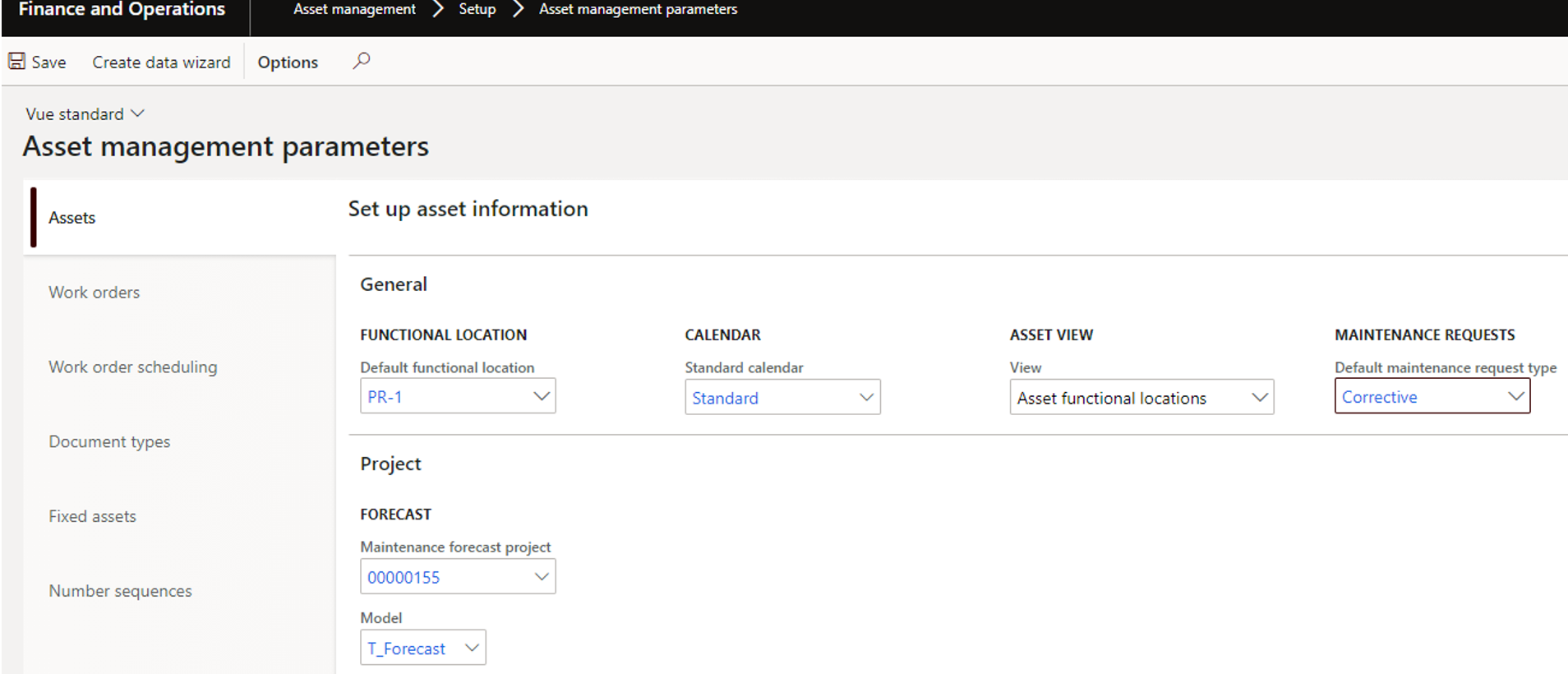

On Asset management > Setup > Asset management parameters, fill the Maintenance forecast project to use (in my case the template designed previously) and the appropriate forecast model.

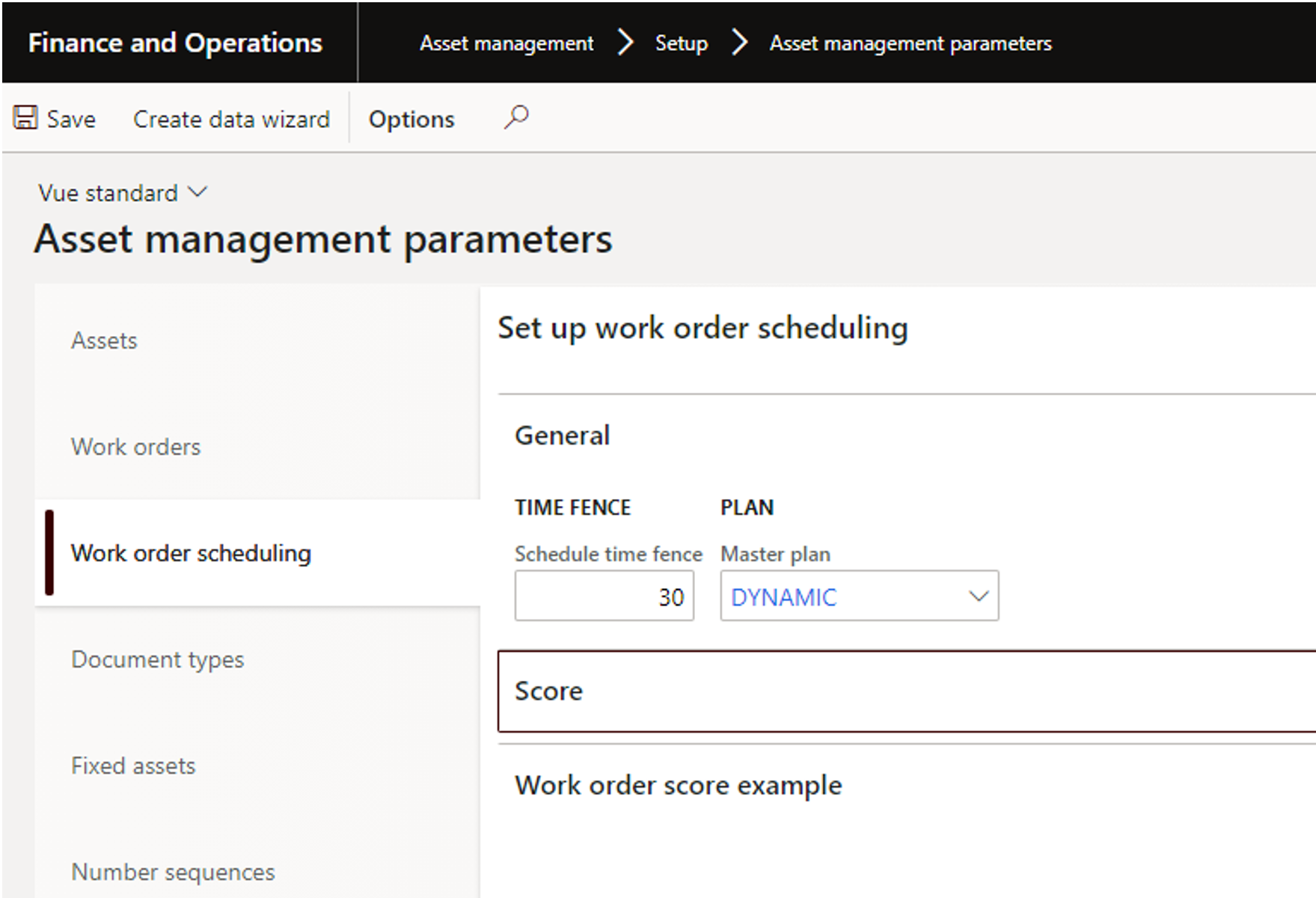

In the Work order scheduling tab, fill the Master plan to use.

Asset

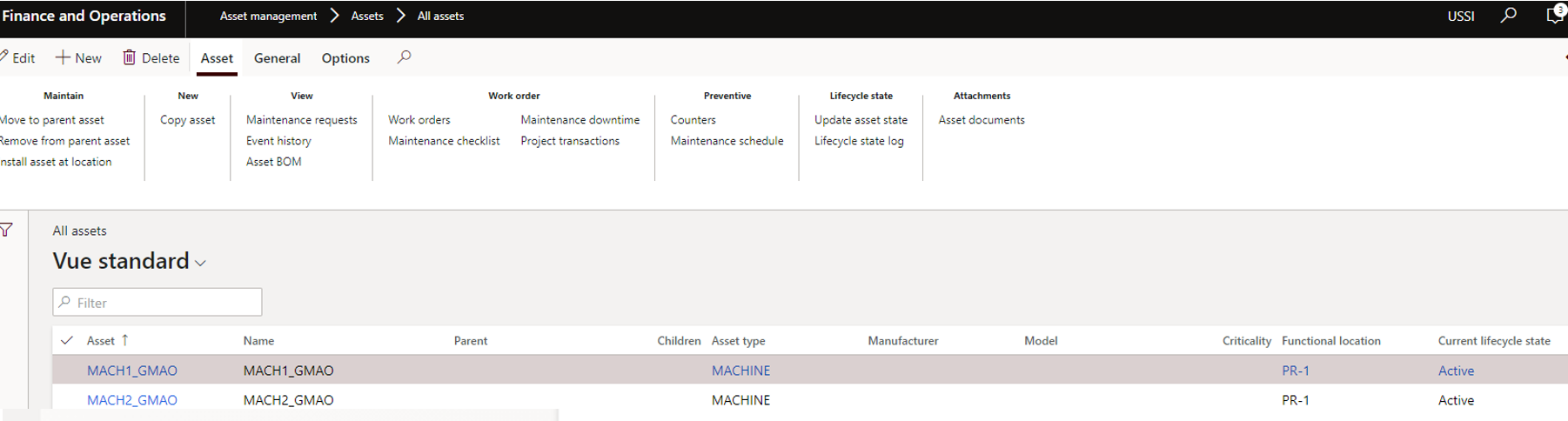

Let’s have a look on my data used. I’ve 2 assets, 2 machines here, created in the same functional location.

Production setup

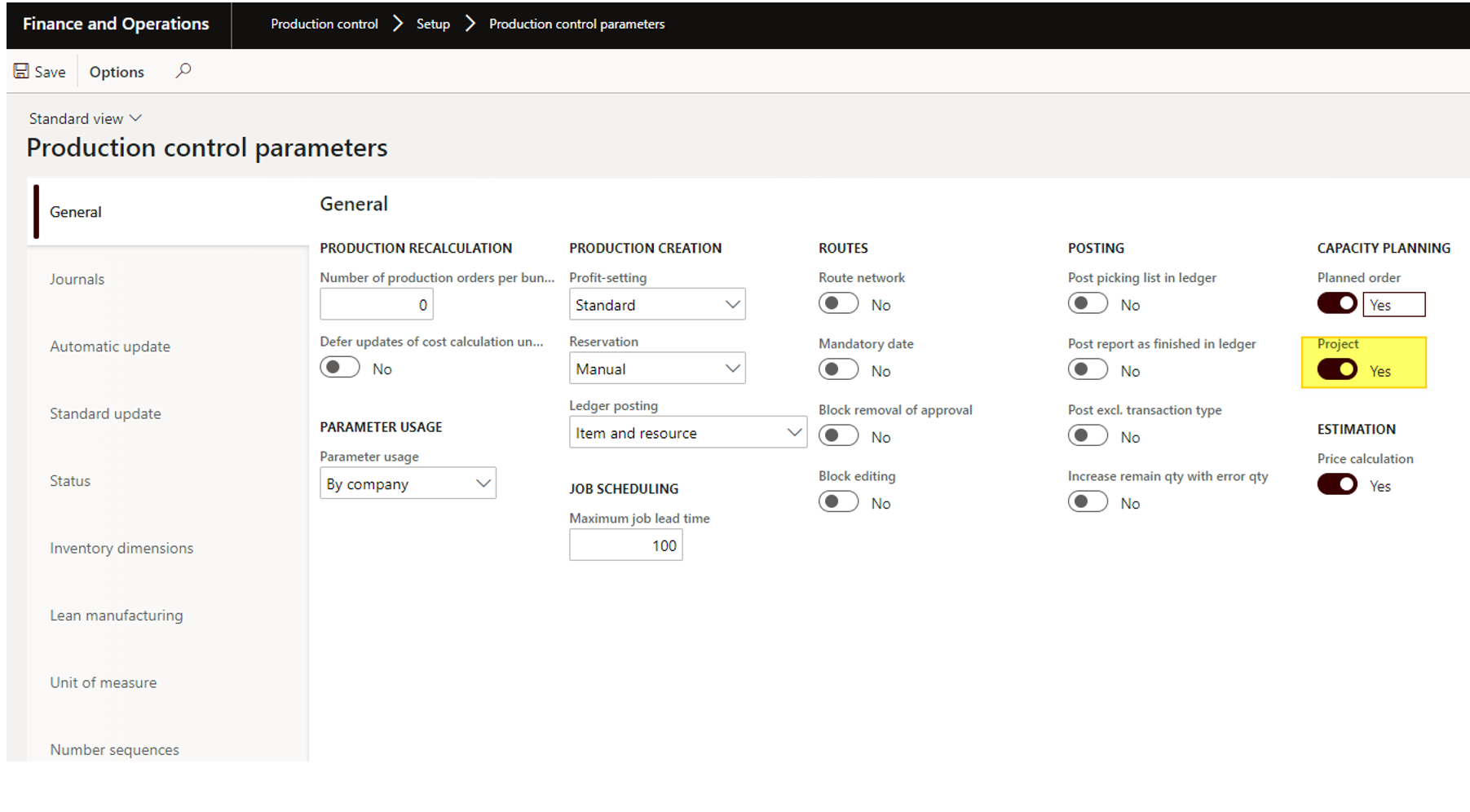

On production setup, available in Production > Setup > Production control parameters, don’t forget here to take into account the Project capacity as well.

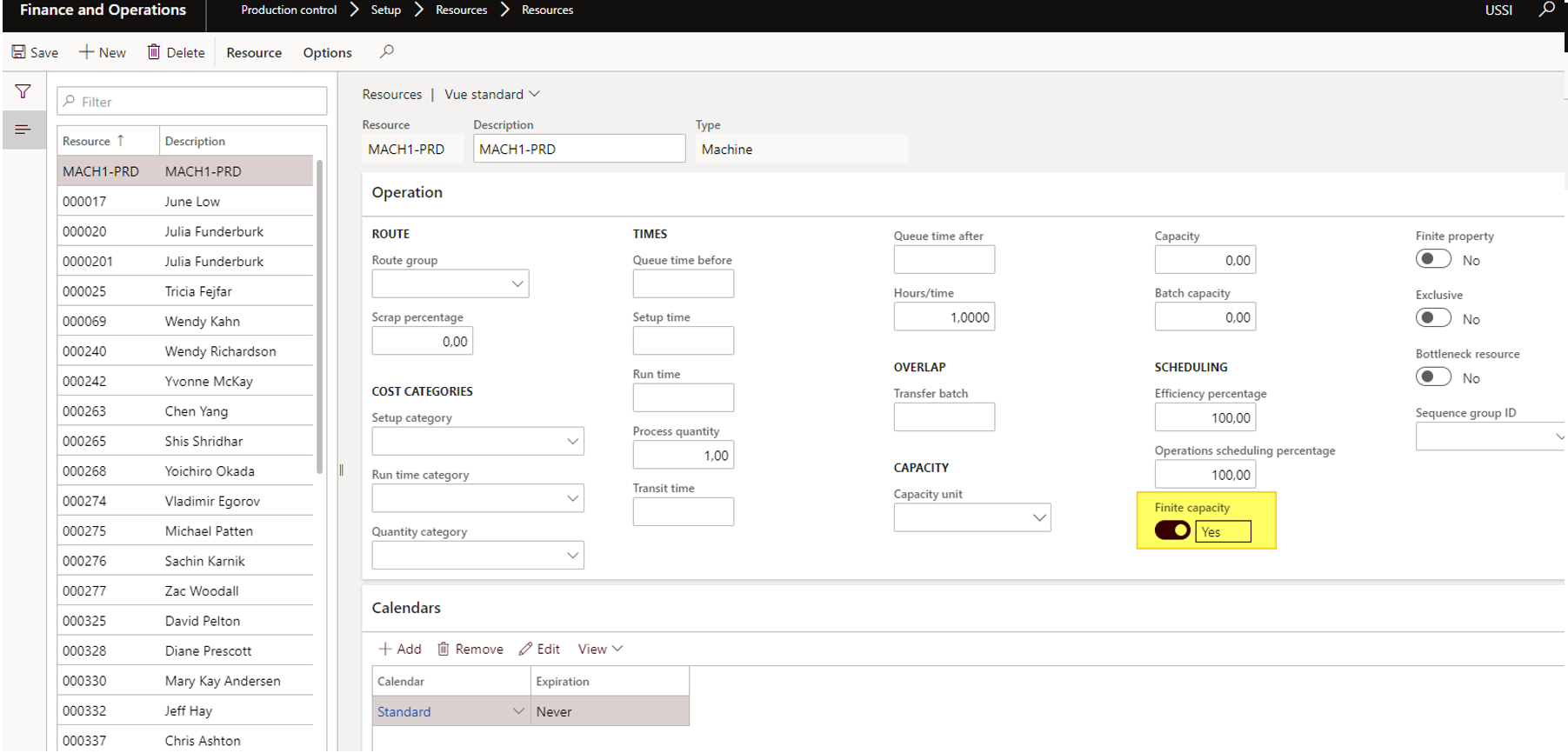

If created in mirror of the Assets 2 production resources, in finite capacity, linked to the same resource group.

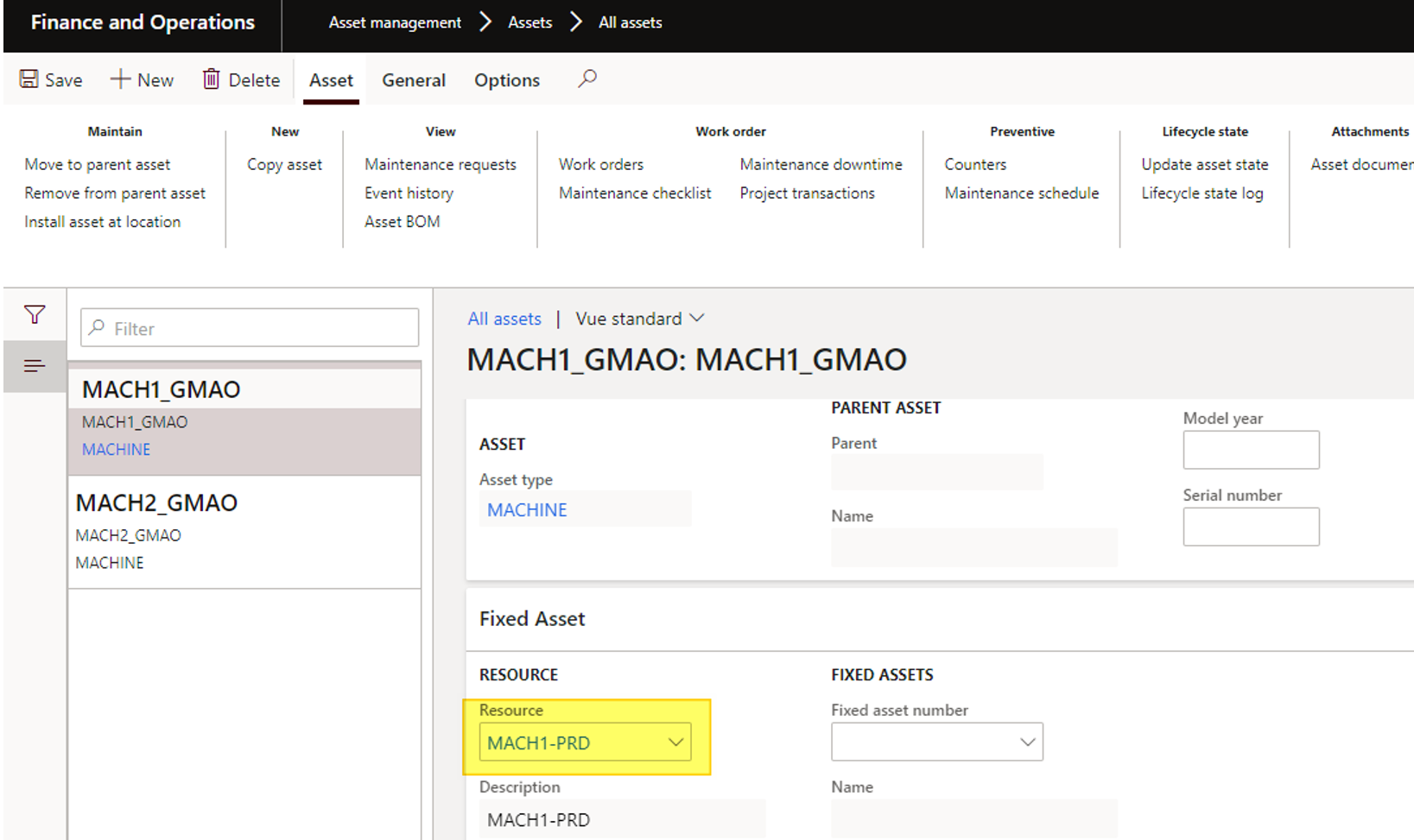

Going back to the asset management, I’m linking the assets to the resources.

This is the end of the setup. Now let’s focus on the process.

Creation of a work order

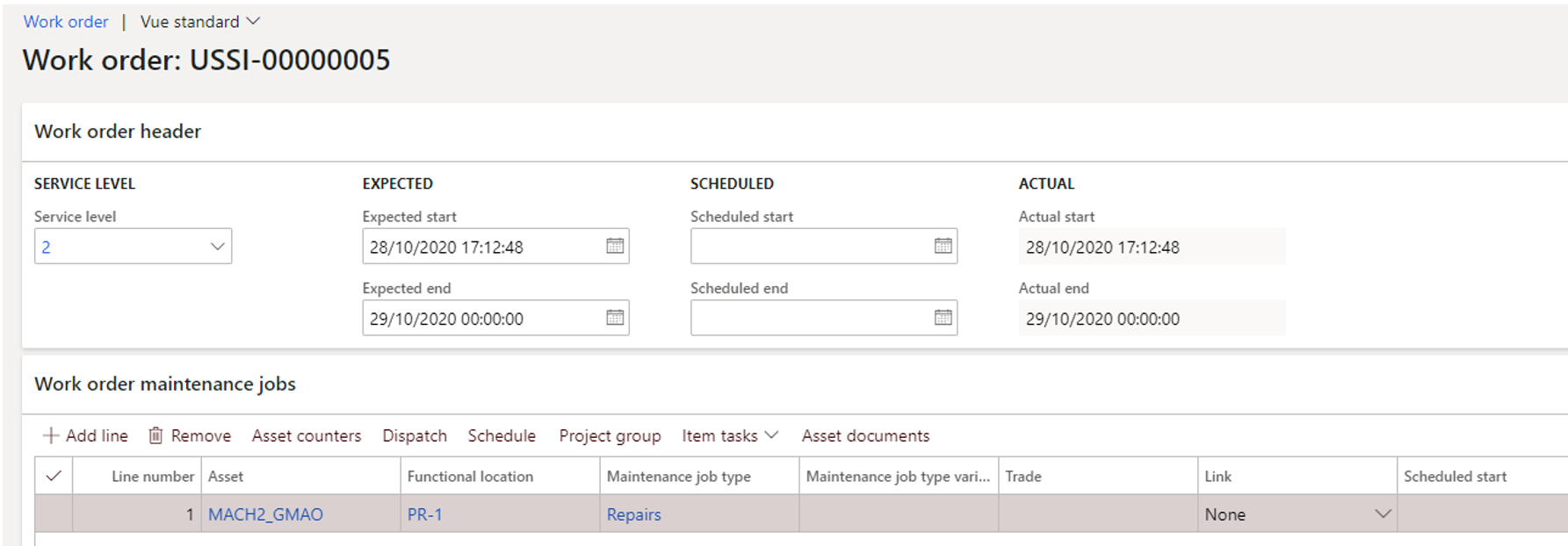

Let’s consider creating a work order (without any maintenance request, the goal is to see the impact on production resource).

I’ve added the MACH2 asset here.

As it’s a corrective work order, if you go see the project used for corrective work orders, you will notice that a subproject has been created.

Having a look at the forecast on that subproject, a line has been generated which corresponds to the work order line.

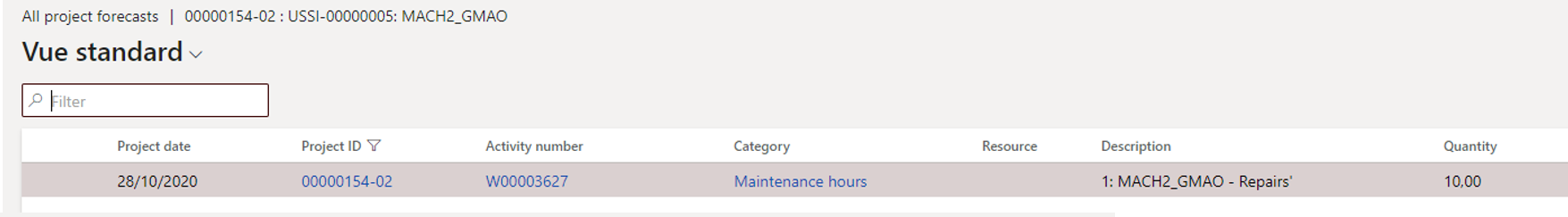

Going back to the work order, I can now schedule it directly from the line.

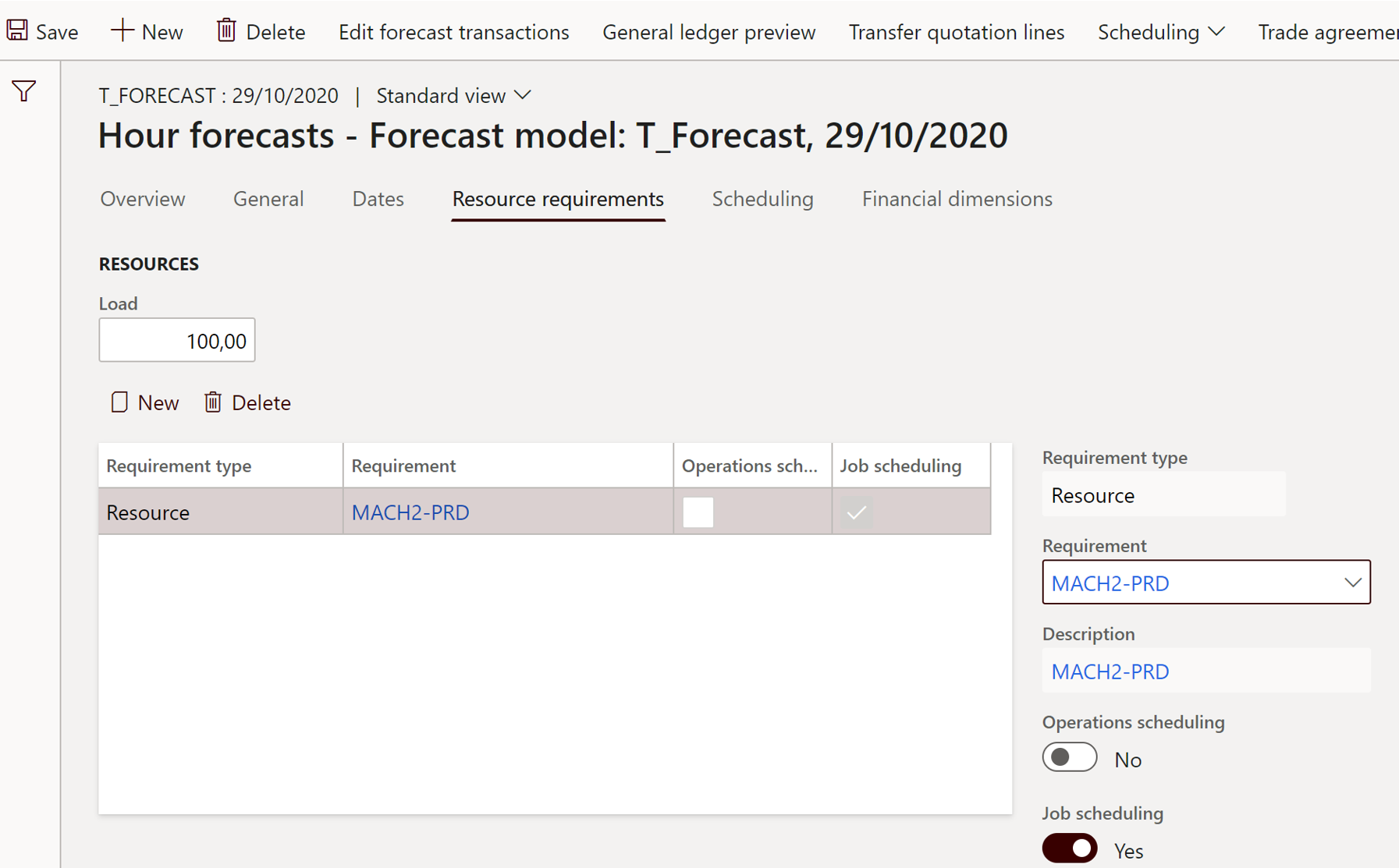

On that form, I’ve added the production resource MACH2 for a quantity of 11 hours maintenance.

Note : I’m a little bit disappointed that I need to add the resource manually here as it’s has been setup on the asset. Why do we need to do it manually ?

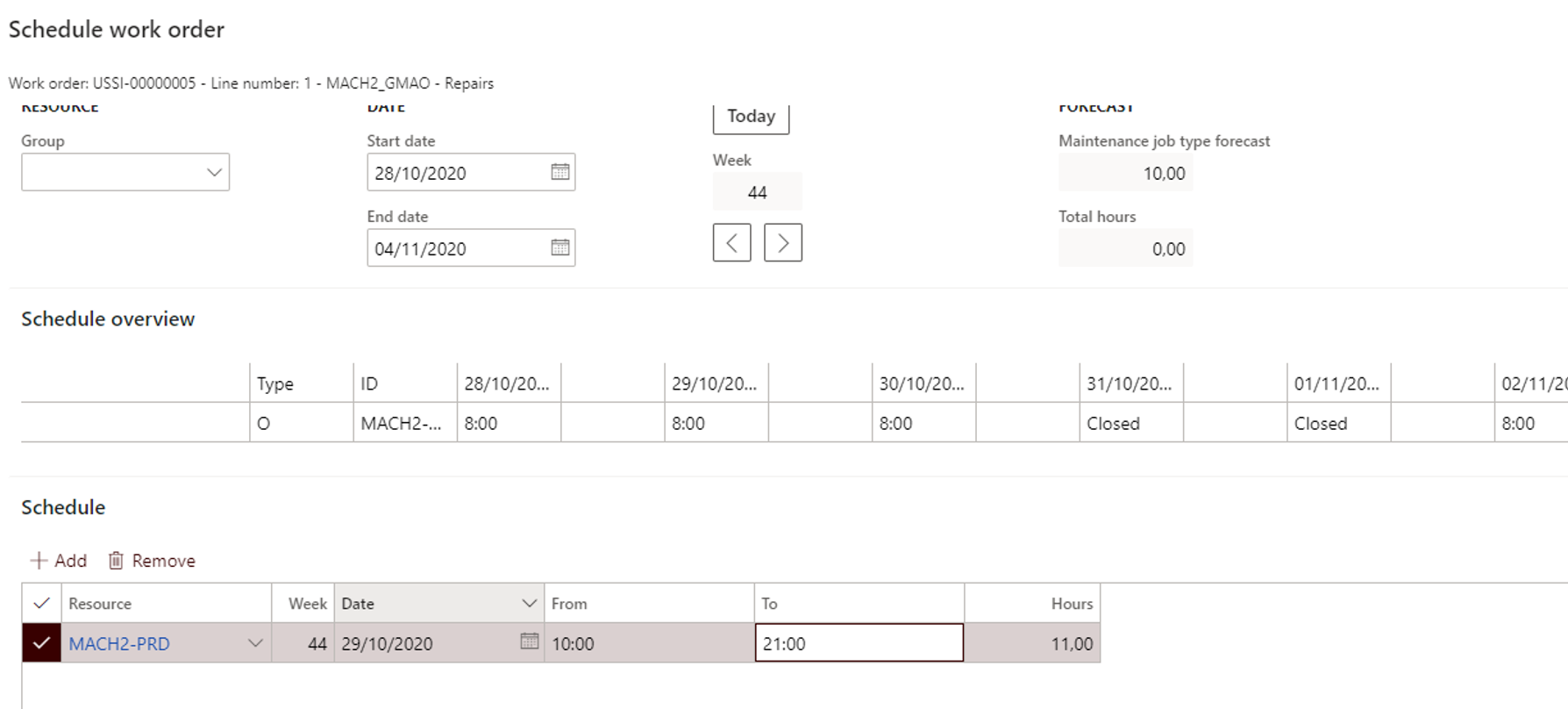

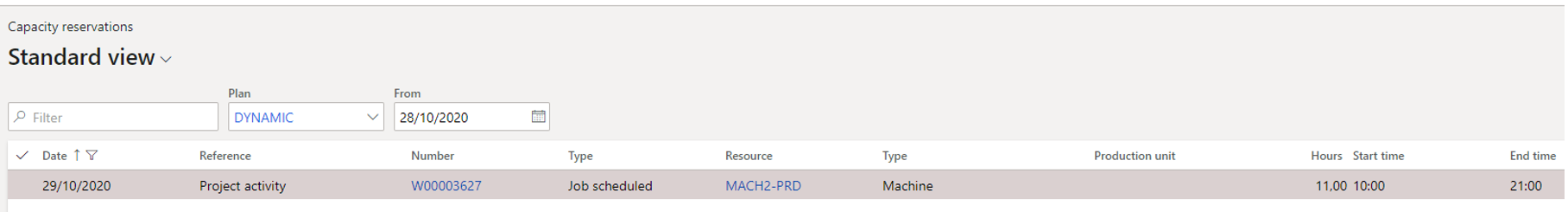

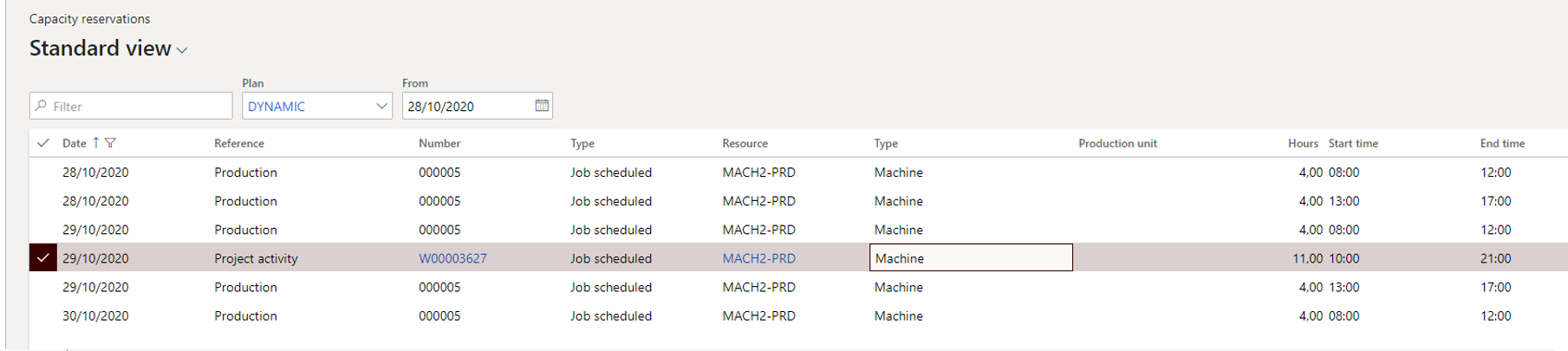

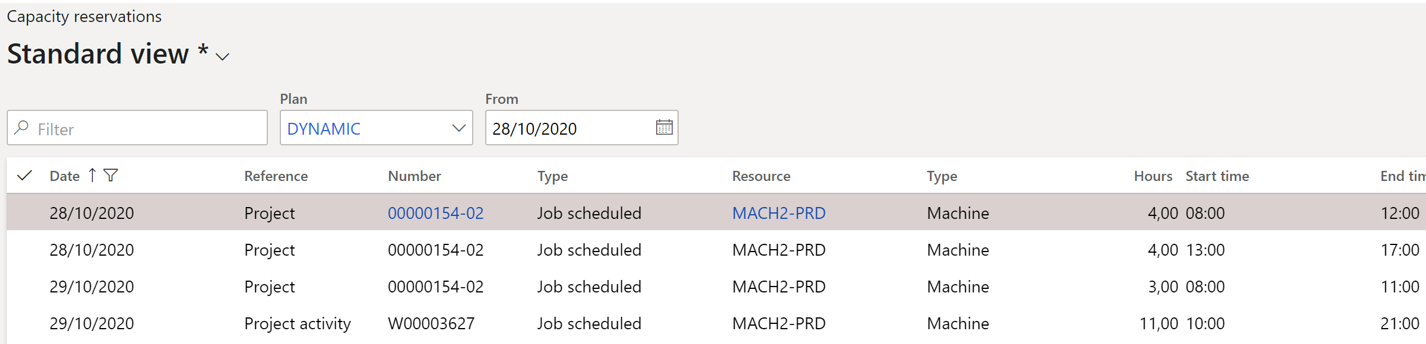

Let’s open the capacity reservations form, available on the Production control module, to see the impact : perfect, the project activity is retrieved here, for 11 hours.

To be sure to have what I’m expected, I’m creating a production order, using the MACH2 resource on my route operation, and then I’m running the job scheduling in finite capacity to check if the maintenance is taken into account.

See the result : no impact of finite capacity. As you can see on the 29th of October, the production order has been scheduled even if the MACH2 is under maintenance.

It’s not over… but you will have to do several manual steps. First I’ve reseted the production order status to estimated.

On the project forecast; edit the forecast and go to the resource requirement tab. In here I’ve added the production resource MACH2 and activate the job scheduling flag on it.

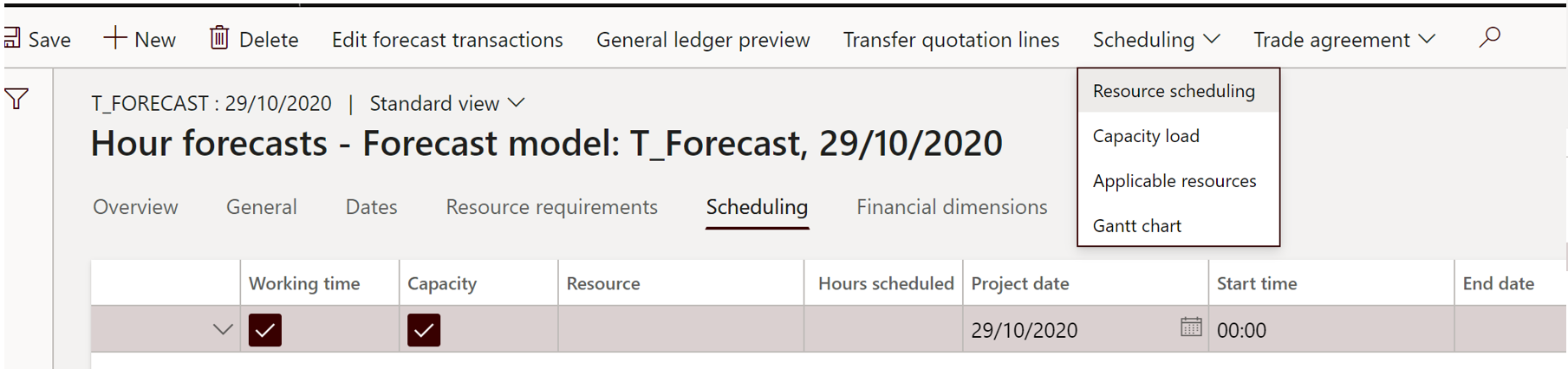

From there, you can run the Resource scheduling functionality. The problem – in my point of view – is that you need to do the last 2 steps manually which is not convenient in the “real life”.

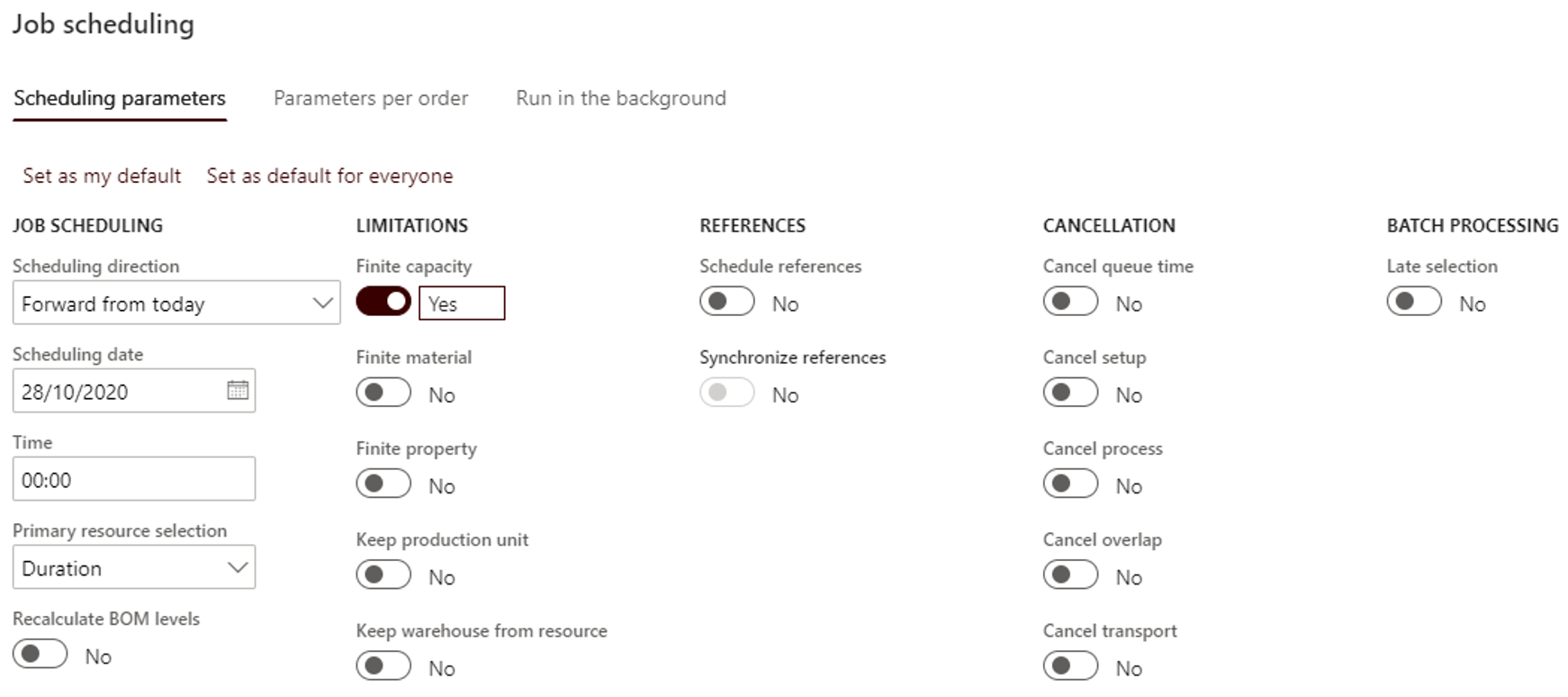

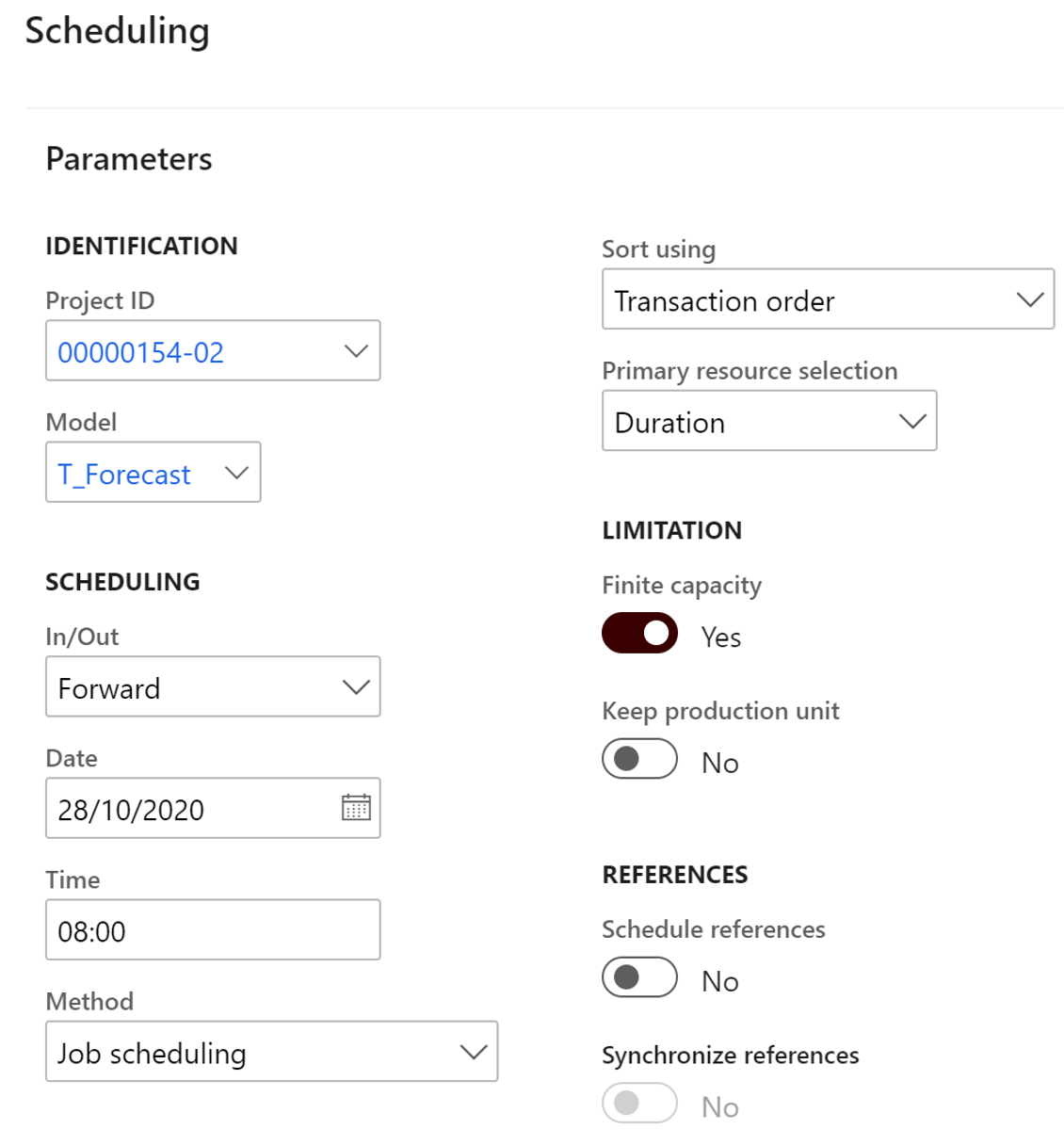

Here we are, be careful to setup properly the parameters before posting the scheduling meaning : finite capacity, job scheduling, and forward (for instance).

After that, go back into the Capacity reservation view from the Production Control module and see the results :

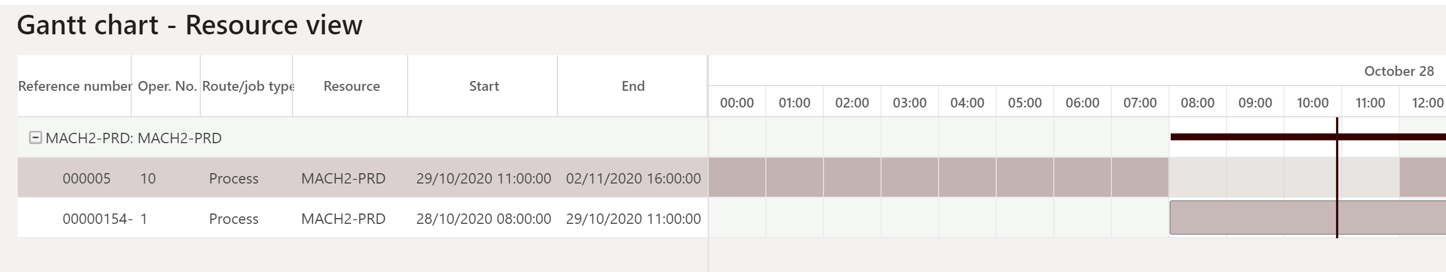

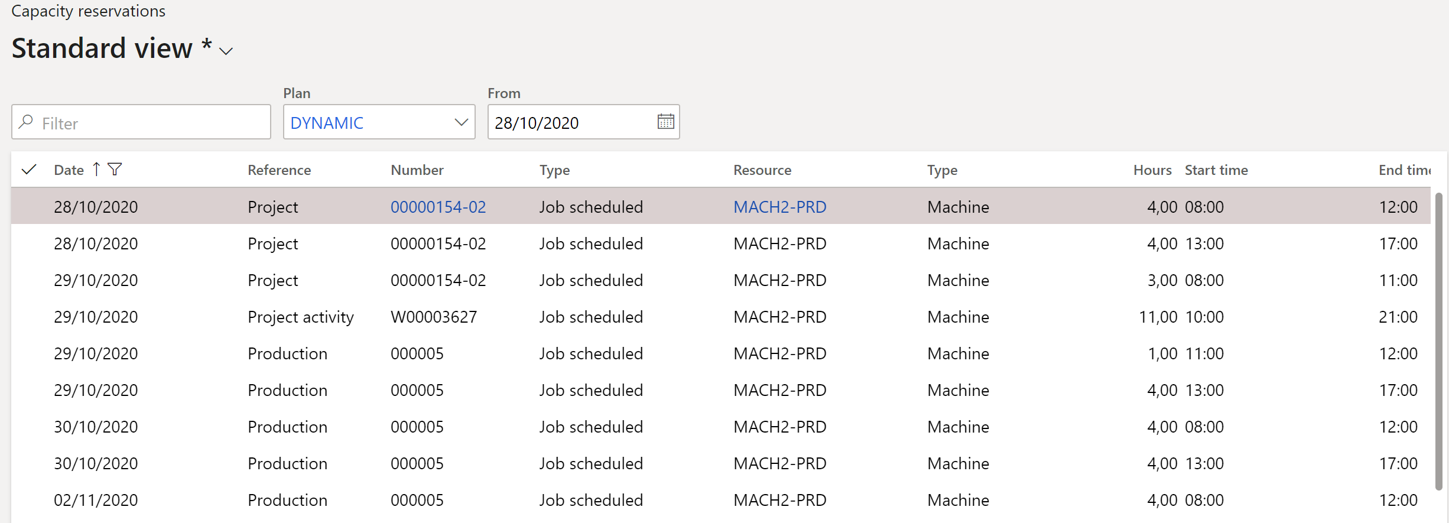

The 28th is busy and job scheduled for the project, meaning for the maintenance of MACH2. If now I run the job scheduling on production order, retrieve the result on the Gantt Chart :

You can see the second line the MACH2 is reserved for the project 154-1 and the maintenance.

In addition, by viewing the capacity reservation here you notice the maintenance has been taken into account as expected.

To conclude, it works at the end but with too many manual adjustments in my opinion.

Just an important note : I was testing on a 10.0.0.12 PU36 environment.

In 10.0.16 release, Microsoft will introduce some enhancements to the integration between Asset management and production.

- New reservation type: Asset work order will be introduced. This will be replacing the use of the reference type: Project activity, that has currently been used for reserving capacity for maintenance work order lines.

- Ability to filter on the new reservation type for asset work orders in various capacity view: Capacity load, Capacity load, graphically, Capacity reservations.

- Ability to load the jobs for Asset work orders into the Gantt chart. A separate tab is added the Content dialog where you can load Asset data.

So let’s just wait Q1 2021 to discover some expected improvements and I will update this post for sure.

Yohann

Hi Johann, thank you very much for sharing these notes. I have a point to add.

1. You don’t have to add the resource when the work order is scheduled if you schedule the work order from Schedule option of the form action pane.

Route: Action pane -> General -> Schedule -> Schedule

2. You don’t have to do the two steps to impact on the finite capacity of the resource. You must to remove the master plan in the asset management parameters for the capacity have an impact.

Regards,

Hello all,

very helpful article.

Can I ask for help? I tried the solution from point 2 and it worked perfect but after I activated the feature Resource planning with maintenance in version 10.0.0.16, the field for Master plan disappeared from Asset management parameters and now the capacity is not finite. So, now I can schedule a production order to be executed at the same time when a maintenance is performed.

Please, tell me if there is a setup that replaces the old one in order the scheduling to work as before.

Thank you in advance.

Bonjour,

j’ai été surpris par le début de l’article pour la séparation des rôles entre Fields Services et Asset Management. Au vu de la capacité de de D365FO de facturer (lien avec le module Projet et des line Properties), il est possible de facturer des prestations de maintenance. Donc il est possible de traiter des actifs en dehors du scope interne de l’entreprise.

Je n’ai pas vu de message de la part de MS indiquant de réserver la partie Asset Management à une utilisation interne (mais je cherche encore…).

L’apport de Fields Services, dans la compréhension, est surtout la capacité à planifier les techniciens (sujet très limité dans D365FO-Asset Management).

Es-tu d’accord ?

Cdlt, Lionel

Salut Lionel,

Depuis peu il est possible de gérer des projets clients (régie/prix fixe) dans le module asset en effet. On pourrait donc envisager d’avoir des assets clients à gérer aussi là.

j’ai échangé avec des experts produits chez MS qui m’ont confirmé cette « tendance » pour différencier Field Service et asset.

Je pense que la problématique c’est d’identifier les besoins en mobilité, optimisation des tournées des techniciens, sur lequel je suis d’accord Field Service est plus approprié. Ce qui est sur, c’est que Field Service s’adresse à des assets clients, tu es obligé de renseigner un client (après tu peux avoir un client « interne »).

En résumé l’approche n’est pas si évidente. Il faut aussi voir la question des licences car le module Asset Management est licencié en fonction du nombre d’assets à gérer…. donc si tu mets tous les assets clients ça va chiffrer pas mal.

A+

Bonjour,

Merci pour cet echange j’essaye de faire une etude afin de montrer les differences entre D365 AM et D365 FS et j’ai beaucoup de mal a trouver des infos en ligne.

je ne comprends pas la strategie de MS a s’acheter EAM de dynaway alors que FS peut faire l’affaire

vos retours seront les bienvenue

Merci

Charles

Merci beaucoup, ça m’a énormément aidé. malheureusment qu’à la fin il fallait opérer des choses manuellement. mais je pense que ça sera corrigé par MS.

Salut,

Si je peux préciser sur les licences, le sujet reste flou dans les conversations avec Microsoft mais il semblerait que seuls les Assets parents soient prises en compte dans le calcul des assets par licence (100 Assets/tenant/month). Les Assets qui sont donc au niveau le plus bas dans une structure hiérarchique d’Assets ne sont donc pas considérés dans le calcul des licences. Le post en question sur le sujet : https://www.yammer.com/dynamicsaxfeedbackprograms/threads/1083545249013760

A+

Evan